In the world of industrial manufacturing, the demand for efficient, high-performance adhesives has driven the development of innovative solutions for a wide range of applications. Among these solutions, adhesive hot melt glue films have emerged as a versatile and reliable choice, particularly in industries such as footwear and textiles. This article delves into the key features, benefits, and applications of adhesive hot melt glue films in the shoe and textile industries, offering insights into their role in enhancing production processes, improving product quality, and driving sustainability.

What is Adhesive Hot Melt Glue Film?

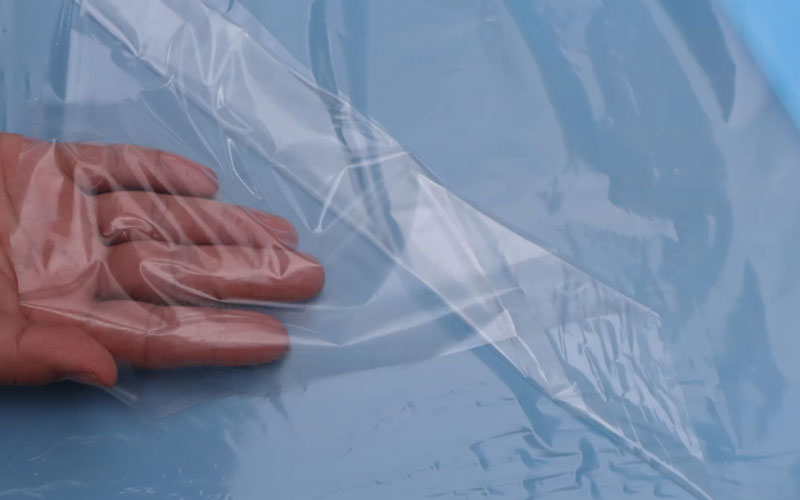

Hot melt adhesive glue films are thermoplastic materials that become soft and tacky when heated. These films are composed of polymers, resins, and additives that are specially formulated to provide a strong bond when applied to different substrates. Once heated, the adhesive films are applied to surfaces, where they solidify upon cooling, forming a strong, durable bond. Unlike liquid adhesives, which can be messy and require careful application, hot melt glue films provide a cleaner, more precise method of bonding, reducing the risk of excess adhesive and improving overall production efficiency.

Benefits of Hot Melt Adhesive Glue Films for Shoes and Textiles

Strong Bonding Capabilities: One of the most notable advantages of hot melt adhesive glue films is their exceptional bonding strength. These films are capable of adhering to a wide variety of materials commonly used in the shoe and textile industries, such as leather, fabrics, synthetic materials, and rubber. Whether it’s for bonding shoe soles to uppers or laminating fabrics for garments, hot melt adhesive glue films offer strong, long-lasting bonds that are crucial for ensuring product durability and performance.

Enhanced Production Efficiency: In the shoe and textile industries, speed and efficiency are vital to meeting the high demands of consumers. Hot melt adhesive glue films are designed for rapid bonding, which significantly reduces production time. Unlike traditional adhesives that may require prolonged drying or curing times, hot melt glue films solidify almost instantly upon cooling, allowing manufacturers to streamline their processes and achieve higher throughput. This fast curing time is especially beneficial for large-scale operations where efficiency is paramount.

Cleaner Application: Liquid adhesives can be messy and difficult to control, often resulting in excess glue that can create waste and require additional cleaning. In contrast, hot melt adhesive glue films are applied as solid sheets or films, offering greater precision and minimizing waste. The adhesive is applied only where needed, reducing the risk of unwanted residue and ensuring a cleaner, more uniform application. This cleaner process is advantageous in maintaining a high-quality finish, particularly in industries where aesthetics and presentation are crucial, such as footwear and fashion.

Flexibility and Durability: Hot melt adhesive glue films are highly flexible and durable, making them ideal for applications in both the shoe and textile industries. For shoes, the ability to bond materials such as leather, fabric, and rubber ensures that the final product is both comfortable and long-lasting. In textiles, these adhesives can be used to laminate different fabric layers without compromising the material’s flexibility or softness. Additionally, hot melt glue films are resistant to wear and tear, moisture, and temperature fluctuations, ensuring that the adhesive bond remains intact throughout the life of the product.

Environmentally Friendly: As sustainability becomes an increasingly important focus for manufacturers and consumers alike, hot melt adhesive glue films offer an eco-friendly alternative to traditional adhesives. These films contain no solvents or volatile organic compounds (VOCs), which helps reduce environmental pollution and the risk of health hazards associated with solvent-based adhesives. Additionally, the precise application of hot melt glue films reduces waste, making them a more sustainable choice in manufacturing processes.

Versatility in Application: Hot melt adhesive glue films are versatile in their application across a range of processes, making them suitable for various uses in both the shoe and textile industries. These films can be used for bonding, laminating, sealing, and coating different materials, providing manufacturers with a one-stop solution for many of their adhesive needs. Whether it’s for the lamination of fabrics, bonding shoe components, or attaching decorative elements to garments, hot melt adhesive glue films can be adapted to meet the unique requirements of different products.

Applications in the Shoe Industry

Shoe Upper and Sole Bonding: One of the primary uses of hot melt adhesive glue films in the shoe industry is for bonding the upper portion of the shoe to the sole. The adhesive film provides a strong, flexible bond that can withstand the stresses and strains of daily wear. This application is particularly useful in the production of athletic shoes, boots, and casual footwear, where durability and comfort are paramount.

Shoe Insole Lamination: Hot melt adhesive glue films are also used in the lamination of insoles in shoes. These films provide a comfortable and secure attachment between the insole and the shoe’s interior, ensuring that the insole remains in place during use. The flexibility of the adhesive allows for the creation of insoles that are both comfortable and durable.

Heel and Toe Cap Attachment: Hot melt adhesive glue films are commonly used to attach heel and toe caps to shoes, providing additional reinforcement and protection to these high-wear areas. The adhesive ensures a strong, secure bond, enhancing the shoe’s overall durability and extending its lifespan.

Applications in the Textile Industry

Fabric Laminating: In the textile industry, hot melt adhesive glue films are used for fabric lamination, which involves bonding multiple layers of fabric together. This process is common in the production of outerwear, activewear, and technical textiles, where additional layers are required for insulation, waterproofing, or structural integrity. The adhesive ensures a seamless bond without compromising the fabric’s softness or flexibility.

Decorative Elements and Embellishments: Hot melt adhesive glue films are ideal for attaching decorative elements, such as appliqués, embroidery patches, and embellishments, to garments. The precise application of the adhesive ensures that these elements are securely bonded to the fabric, reducing the risk of detachment during wear or washing.

Seam Sealing and Waterproofing: In the production of outdoor clothing, hot melt adhesive glue films are used for seam sealing and waterproofing applications. The adhesive creates a barrier that prevents water from seeping through seams, ensuring that the garment remains waterproof even in harsh weather conditions.

Conclusion

Adhesive hot melt glue films are revolutionizing the shoe and textile industries by providing an efficient, versatile, and environmentally friendly adhesive solution. With their strong bonding capabilities, quick curing time, and cleaner application, these films have become indispensable in the manufacturing of footwear and textiles. As the demand for high-performance, sustainable products continues to rise, hot melt adhesive glue films are set to play an even more significant role in shaping the future of these industries, offering manufacturers a reliable solution to meet the challenges of modern production while maintaining high-quality standards.