Non-woven bags are made of non-woven fabrics as raw materials and produced by non-woven bag making machines. No auxiliary materials and solvents are added in the middle. Therefore, it is also a green product. It is also tough and durable, beautiful in shape, breathable, reusable, washable, and can be screen-printed with advertisements and trademarks. Suitable for any company and any industry as advertising and gifts.

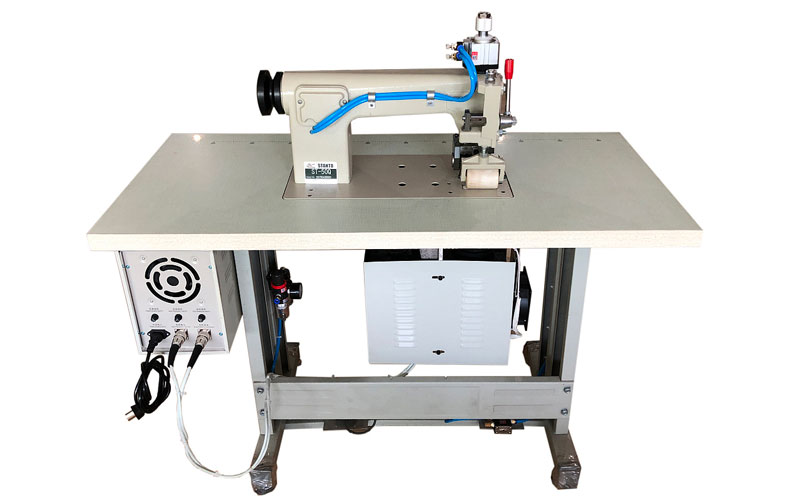

There are two types of equipment for making non-woven bags: fully automatic non-woven bag machines and ultrasonic lace machines (semi-automatic non-woven bag machines).

Fully automatic non-woven bag machines have high automation and high efficiency. They are mainly used for the production of flat bags, side bags, bottom bags, etc., so they are widely used in large non-woven bag manufacturers with fixed orders.

At present, non-woven bags are still mainly made in family workshops, and non-woven bags are processed according to customer requirements. In these factories, fully automatic non-woven bag machines are not very practical, and most of them use semi-automatic production equipment.

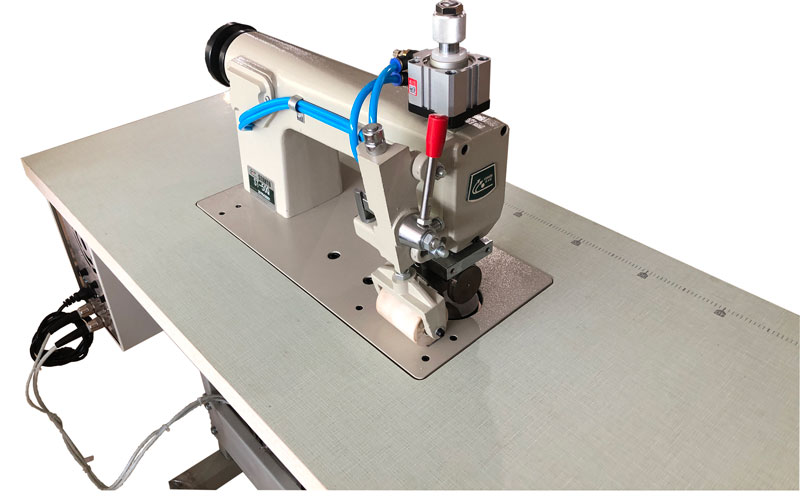

The working principle of the ultrasonic lace machine is to use high-frequency oscillation to transmit sound waves from the welding head to the welding surface of the workpiece, instantly causing friction between the molecules of the workpiece to reach the melting point of the plastic, thereby completing the rapid dissolution of the solid material and completing the welding. The strength of its joint point is close to that of a whole piece of continuous material. As long as the joint surface of the product is designed to match, there is absolutely no problem with complete sealing.

Two Application of Ultrasonic Lace Machine in Making Non-woven Bags

In the production process of non-woven bags, ultrasonic lace machines have the following two main uses. Let’s take a look at them with Alster:

- Non-woven bag sewing: using ultrasonic welding, no needle and thread, saving the trouble of frequent needle and thread changes, no broken thread joints of traditional thread sewing, and neat partial shearing and sealing of non-woven bags. While sewing, it also plays a decorative role, with strong adhesion, waterproof effect, clear embossing, more three-dimensional relief effect on the surface, fast working speed, good product effect, more high-end and beautiful; quality is guaranteed.

- Making of hand straps: Connect the ultrasonic lace machine and a shearing machine together, and set the ultrasonic lace machine to automatic, which can automatically make hand straps.

Ultrasonic lace machines (semi-automatic non-woven bag machines) are widely used in the packaging industry, clothing industry, beauty industry, service industry, home appliance industry, non-woven clothing, office supplies, toy industry, etc. Used to make environmentally friendly non-woven products such as eco-friendly bags, gift bags, shopping bags, advertising bags, non-woven bags, gift bags, non-woven handbags, non-woven hanging bags, cosmetic bags, suit bags, advertising aprons, non-woven computer covers, TV covers, air conditioner covers, washing machine covers, dust cover covers, etc.

As a professional manufacturer and provider of seamless bonding machine and hot melt adhesive products in the clothing and textile fields, Alster provides a variety of bonding machines. Welcome to contact us for professional product consultation.