Hot melt adhesive mesh and hot melt adhesive film are products made through different production processes. Want to know the difference between hot melt adhesive film and web? Follow us! Hot melt adhesive mesh is usually formed by applying hot melt adhesive on a mesh-like substrate to form a mesh with good air permeability, which is suitable for applications that require air permeability, such as clothing and medical patches. In contrast, hot melt adhesive film is formed by directly applying hot melt adhesive on the substrate to form a continuous adhesive film with higher viscosity and sealing, which is suitable for occasions that require strong adhesion and waterproofness. Due to different production processes, there are significant difference between hot melt adhesive film and web in terms of cost, air permeability and viscosity.

Difference Between The Production Process of Hot Melt Adhesive Film and Web

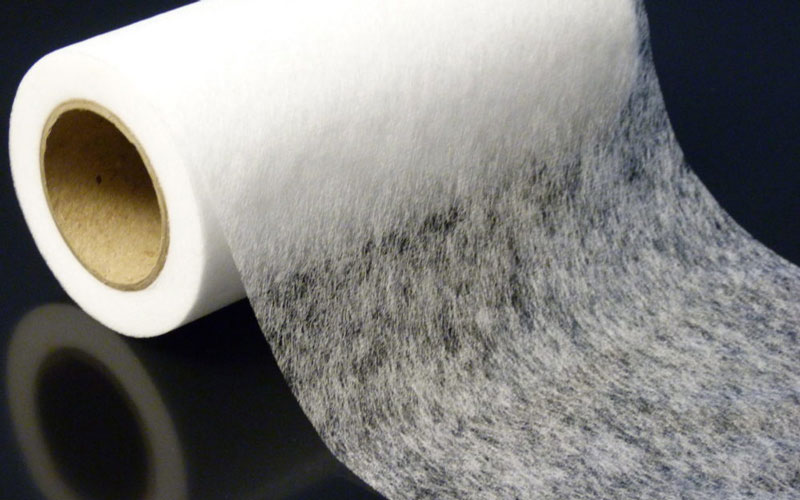

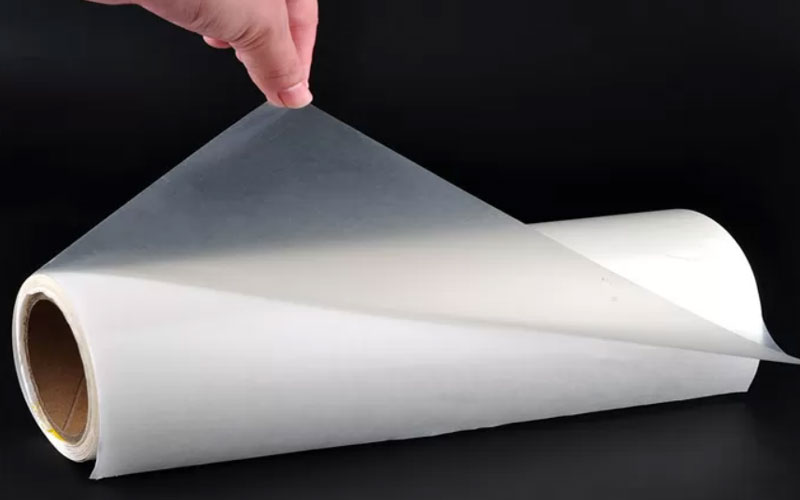

Hot melt adhesive web and adhesive film are both hot melt adhesive products, but the production process is different. Hot melt adhesive web is made by melting hot melt adhesive through an extruder and then using melt-blown web forming method. It looks similar to non-woven fabrics and is packaged in rolls. You can check hot melt adhesive web for more information; while hot melt adhesive film is made by melting hot melt adhesive through an extruder and then using a doctor blade, laminating machine or blow molding machine. It looks similar to a film and is packaged in rolls. You can check hot melt adhesive film for more information.

Difference Between the Cost of Hot Melt Adhesive Film and Web

The commonly used hot melt adhesive mesh film is much cheaper than the commonly used hot melt adhesive film. This is mainly because the commonly used hot melt adhesive mesh film has a low gram weight, mainly 15g/㎡-30g/㎡, while the commonly used hot melt adhesive film is usually 0.03mm, 0.05mm, 0.10mm thick, converted into a gram weight of generally 28g/㎡-120g/㎡, the glue content is much higher, so the price is also more expensive. Of course, if the gram weight of the hot melt adhesive mesh film and the hot melt adhesive film is similar, the cost is not much different. At the same time, some models of hot melt adhesive films are equipped with release paper, which will increase the additional cost of the film. Therefore, the most intuitive feeling for everyone is that the price of hot melt adhesive film is more expensive.

Difference in Breathability Between Adhesive Film and Web

Difference in Viscosity Between Hot Melt Adhesive Film and Web

Differences in the Application Fields of Film and Web

Application Fields of Hot Melt Adhesive Film

Application Fields of Hot Melt Adhesive Web

Through the above content, I believe you have a basic understanding of hot melt adhesive film and hot melt adhesive mesh. If you want to purchase these two types of hot melt adhesive products in bulk, please contact Alster!