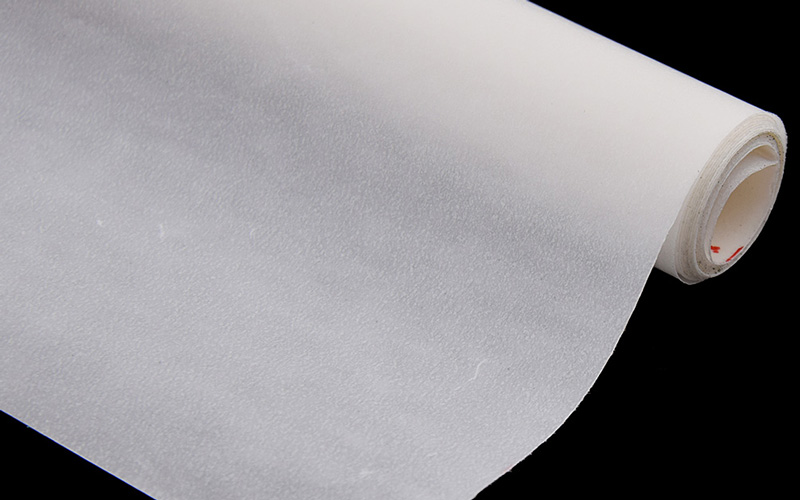

Hot melt adhesive film and hot melt adhesive web film can basically be divided into specifications with backing paper (with release paper) and without backing paper (without substrate). Want to know the difference between hot melt adhesive film with and without backing paper? Usually, hot melt adhesive web films are without backing paper, and those with backing paper need to be customized. Among hot melt adhesive films, those with backing paper and those without backing paper each account for half. The following will introduce the differences between those with and without backing paper and their advantages and disadvantages to help you choose products according to your needs. If you want to buy hot melt adhesive film with and without backing paper, feel free to contact Alster!

Different Use of Hot Melt Adhesive Film With and Without Backing Paper

The main difference between hot melt adhesive film with and without backing paper is the method of use. For example, when using hot melt adhesive film without backing paper, you only need to place it between the two layers of materials to be bonded, and use heating equipment to bond the three layers of materials together, which has high production efficiency; for hot melt adhesive film with backing paper, it is necessary to align the adhesive film with the material to be bonded on one side, use the pressing equipment to heat and press on one side of the release paper, and first bond the adhesive film with the material to be bonded on one side, then wait for it to cool and tear off the backing release paper, and then bond it with the material to be bonded on the other side for the second time, which requires more process steps.

Difference Between Them

| Difference | With Backing Paper Hot Melt Adhesive Film | Without Backing Paper Hot Melt Adhesive Film |

|---|---|---|

| Composition | A layer of backing paper on one side of the adhesive film | No backing paper, adhesive film exposed directly |

| Ease of Use | Need to remove backing paper first, more precise operation | Direct use, but requires careful handling |

| Applications | Suitable for high-precision bonding scenarios | Suitable for large area bonding or non-precise positioning scenarios |

| Protection | Backing paper protects against contamination and damage | Easily affected by the environment, may impact bonding effect |

Advantages of hot melt adhesive film without backing paper

The biggest advantage of hot melt adhesive film and web film without backing paper is that it is easy to operate and low in price, because the bonding process can be completed in one time, which will greatly improve product production efficiency and increase output. At the same time, because there is no release paper, the raw material cost is relatively low when producing hot melt adhesive film web products.

Advantages of hot melt adhesive film with backing paper

The advantage of hot melt adhesive film with backing paper is that it is more convenient to position, which is also an indispensable attribute in some uses. For example, when hot melt adhesive film is used for bonding at the position of clothing pockets, the hot melt adhesive film is usually manually aligned to the corresponding position, and the first ironing is performed by heating one side of the release paper with an iron to fix the film firmly in the designated position, and then the other side of the fabric is bonded. If this process uses a hot melt adhesive film without a substrate, then the three layers of materials need to be bonded at one time, which will cause the film to be easily misaligned in the middle and affect the production of the product.

At the same time, another advantage of hot melt adhesive film with backing paper is that it is easy to cut, whether it is cut when not in use or cut together with the base fabric after the first lamination. This is also convenient for customers who need some local lamination or pattern lamination.

Hot Melt Adhesive Film Manufacturer and Supplier

In general, hot melt adhesive films with backing paper have more advantages in terms of protection and ease of operation, while hot melt adhesive films without backing paper have more advantages in terms of simplified operation and application cost. The choice of hot melt adhesive film needs to be determined according to the specific application requirements and operating environment.

So, through Alster’s introduction, do you understand the difference between hot melt adhesive films with backing paper and hot melt adhesive films without backing paper? Do you know how to choose? If you still have questions about these two hot melt adhesive films, please contact Alster to learn more!