Are you inquiring about seamless bonding machines for your business? Want to learn more about this type of machine? Here, Alster introduces some common questions for you, hoping to help you learn more about seamless bonding machines.

1. What is a seamless bonding machine?

A seamless bonding machine is a machine mainly used in the production of clothing and textiles, which can seamlessly connect fabrics together through hot melt bonding technology. It effectively eliminates the stitching in traditional sewing processes, thereby providing a smooth and beautiful appearance, especially suitable for products with high requirements for appearance and function such as high-end clothing, sportswear and outdoor equipment.

2. The function of a seamless bonding machine

The main function of a seamless bonding machine is to firmly bond fabric materials together without using traditional stitching technology. Through the heating and pressure of hot melt tape, hot melt film, etc., the appearance of the bonded product is smoother and more beautiful, and the functions of clothing such as waterproof and breathable are improved, thereby improving the overall performance and wearing comfort of the clothing.

3. Types of seamless bonding machines

What types of seamless bonding machines are there? There are many types of machines on the market, and there are also many models. The most common ones are the following three:

- Hot melt adhesive bonding machine: By using hot melt tape to bond two pieces of fabric together, it is often used in sportswear, outdoor clothing and waterproof products.

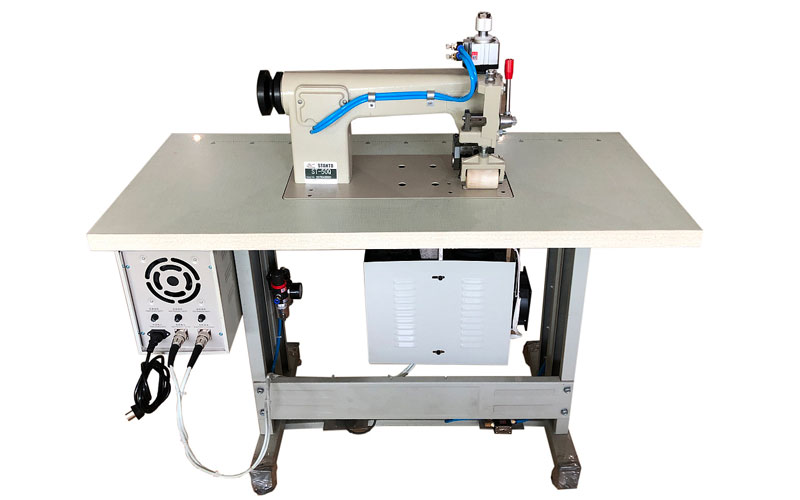

- Ultrasonic bonding machine: It mainly melts and bonds materials through ultrasonic vibrations, and is suitable for seamless underwear, medical textiles, etc.

- RF bonding machine: The fabric is heated and bonded through radio frequency technology, and is often used for film materials, technical textiles, etc.

4. How to use a seamless bonding machine?

After purchasing these machines, how to use them is a question. Usually, these machines are accompanied by detailed instructions and videos of use, etc., and online use guidance services are also provided. The general steps of use are: when using a seamless bonding machine, the material needs to be placed in the working area of the machine, the appropriate bonding parameters (temperature, pressure and time) need to be selected, and then the machine needs to be started.

5. The most common application areas

The main application areas of seamless bonding machines include clothing and textile products, mainly including the following products:

- Sportswear: Seamless bonding technology can eliminate seams and improve the comfort and durability of clothing.

- Outdoor equipment: such as waterproof jackets, tents, etc., use seamless bonding technology to improve waterproof performance.

- High-end fashion: In high-end clothing that pursues beauty and fashion, seamless bonding provides a clean and tidy appearance.

- Underwear: Seamless bonding can reduce friction and improve comfort.

- Medical textiles: such as seamless surgical gowns, protective clothing, etc., to ensure hygiene and safety.

6. Price of seamless bonding machine

Generally speaking, the price of a basic small seamless bonding machine ranges from several thousand yuan to ten thousand yuan, while a large seamless bonding machine with more advanced functions suitable for industrial production may cost tens of thousands or even hundreds of thousands of yuan. The specific price will also vary depending on the manufacturer’s pricing strategy and additional services (such as after-sales support, technical training, etc.). When purchasing, it is recommended to compare according to specific needs and choose a product with a suitable price-performance ratio.

7. Introduction to seamless bonding machine manufacturers

Alster is a professional manufacturer of seamless bonding machines with rich production experience in the field of textile equipment. We provide customers with high-quality equipment, guaranteed service life and comprehensive technical training. Our equipment has been exported to more than 50 countries in the world.

8. What are the advantages of seamless bonding technology?

- Beauty: Seamless bonding technology can eliminate the irregular appearance caused by traditional sewing lines, making the product more beautiful.

- Comfort: Clothing has no seams, which can effectively reduce friction. It is especially suitable for underwear, sportswear and other close-fitting clothing, which is particularly comfortable.

- Versatile: Seamless bonding can achieve multiple functions such as waterproof and windproof.

9. Are seamless bonding machines suitable for all materials?

Seamless bonding machines are not suitable for all materials. Commonly applicable materials include synthetic materials such as nylon, polyester, elastic fabrics, and films, which are easily bonded by hot melt adhesives or ultrasonic technology. For natural fibers, including, linen and cotton, the use of seamless bonding machines may not work well, and usually requires specific glues or treatment processes to achieve good bonding effects.