With the rapid development of the automotive industry, the design and production of car interiors pay more and more attention to comfort, aesthetics and practicality. As an important link in the production of interiors, the selection of adhesive technology directly affects the quality and service life of the interiors. As one of the core materials for bonding car interiors, hot melt adhesive film for automotive interior plays an important role in modern automobile manufacturing and decoration with its excellent performance and diverse application scenarios. This article will discuss in detail why hot melt adhesive film is needed for car interiors, common types and selection requirements.

The role of hot melt adhesive film in car interiors

In car production, the interiors not only need to meet functional requirements, but also must be bonded to achieve a solid combination of materials. Hot melt adhesive film has become an indispensable material for car interiors due to its superior sealing and bonding strength.

The following are the main application areas and functions of hot melt adhesive film in car interiors:

Ceiling

The ceiling is an important part of the car interior, usually composed of textile materials and metal frames. Hot melt adhesive film is used to firmly bond these heterogeneous materials while ensuring the flatness and aesthetics of the ceiling. In addition, hot melt adhesive film can also reduce the noise when the ceiling vibrates and improve driving comfort.

Damping plate

The damping plate is used for sound insulation and noise reduction. Its main function is to absorb vibration and noise. Through the bonding of hot melt adhesive film, the damping plate can be closely attached to the metal surface of the car body, thereby achieving better noise reduction effect.

Foot pad

Hot melt adhesive film is widely used to fix foot pads, which can prevent them from sliding, while increasing durability and waterproof performance to ensure driving safety.

Seat

The structure of the seat is complex and consists of a variety of materials, including leather, cloth, foam, etc. Hot melt adhesive film can effectively combine these materials to improve the firmness and elasticity of the seat, making it more comfortable and durable.

Trunk floor mat

The trunk floor mat needs to withstand greater pressure and friction. Through the bonding of hot melt adhesive film, the floor mat can remain stable and have good waterproof and moisture-proof properties.

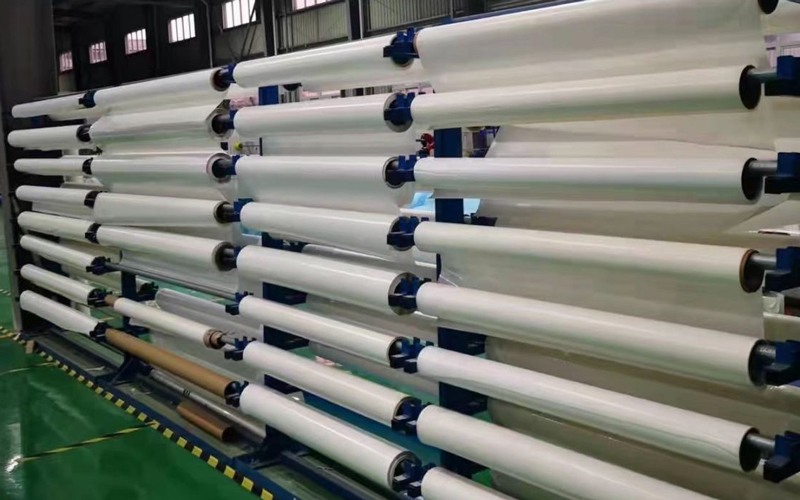

Common types of hot melt adhesive film for automotive interior

There are many types of automotive interior materials, and different materials have different performance requirements for adhesive films. To meet these needs, the following hot melt adhesive films are mainly used in the market:

1. PA hot melt adhesive web

PA (polyamide) hot melt adhesive web is known for its superior bonding strength and heat resistance, and is particularly suitable for interior parts that require high-strength bonding.

- Features: high temperature resistance, strong bonding.

- Application scenarios: complex composite materials, seat structure bonding, etc.

2. PES hot melt adhesive web

PES (polyester) hot melt adhesive web has good flexibility and durability, and is an ideal choice for textiles and composite materials.

- Features: soft, durable, and easy to construct.

- Application scenarios: bonding of ceilings, damping panels and foot pads.

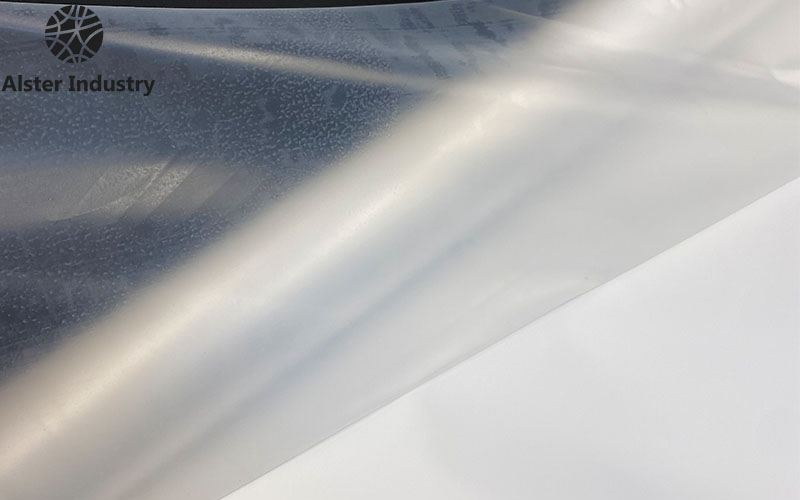

3. TPU hot melt adhesive film

TPU (thermoplastic polyurethane) adhesive film is widely used for parts that require elastic bonding due to its high elasticity and excellent transparency.

- Features: strong elasticity, transparency, and good weather resistance.

- Application scenarios: seat surfaces, elastic decorative parts.

4. PO hot melt adhesive film

PO (polyolefin) hot melt adhesive film is the preferred material for metal bonding, especially in the bonding of aluminum parts.

- Features: strong adhesion to metal surfaces, high temperature resistance, easy construction.

- Application scenarios: metal frames, door trims.

5. EVA hot melt adhesive film

EVA (ethylene-vinyl acetate copolymer) hot melt adhesive film has good adaptability in the bonding of plastics or composite materials, and the price is relatively economical.

- Features: high cost performance and balanced bonding performance.

- Application scenarios: trunk floor mats, plastic decorative parts.

Material selection requirements for hot melt adhesive film for automotive interiors

The hot melt adhesive film used in automotive interiors needs to meet complex bonding requirements, so the performance requirements are as follows:

Multi-material compatibility

Automotive interiors involve a variety of materials such as metals, plastics, and textiles. Hot melt adhesive films need to have a wide range of adaptability and be able to form a strong bond between different materials.

High and low temperature resistance

Automobiles are used in different environments, and interior parts need to withstand high or low temperature tests. Hot melt adhesive film needs to have good thermal stability and weather resistance.

Environmental protection and safety

The modern automotive industry has increasingly higher requirements for environmental protection, and hot melt adhesive film needs to meet environmental standards of non-toxic, harmless and low odor.

Easy construction

In order to meet the high efficiency requirements of automobile production lines, hot melt adhesive film needs to be easy to operate and quickly solidify.

Different parts can choose the appropriate adhesive film according to actual needs. For example, PO adhesive film performs well in metal bonding, while PES adhesive film is more suitable for textiles and composite materials.

Conclusion

Hot melt adhesive film is a key material in automotive interior bonding. It has a wide variety of types and different performances, and can provide customized solutions for different materials and application scenarios. In the future, with the development of automotive technology, the performance of hot melt adhesive film will be further optimized, providing more possibilities for automotive interior manufacturing. If you have any needs or questions about hot melt adhesive film for automotive interior, it is recommended to consult professional suppliers for professional advice and high-quality products.