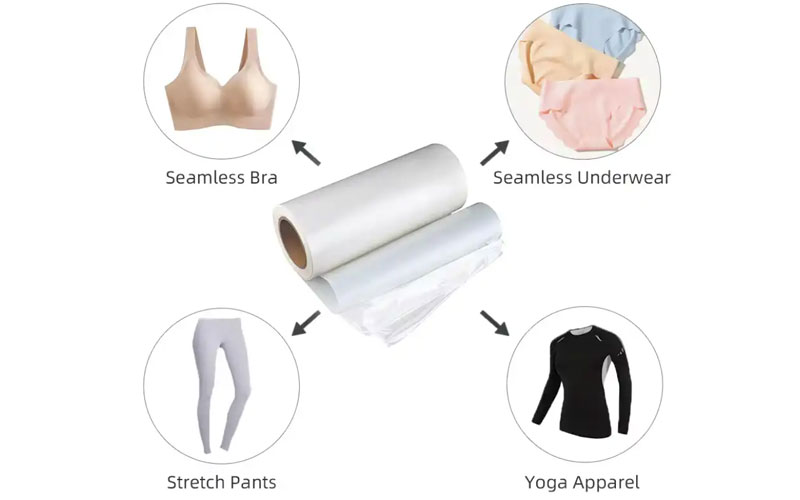

As an important innovation in the clothing industry in recent years, seamless underwear has won the favor of many consumers with its comfort, fit and invisibility. In the process of manufacturing seamless underwear, hot melt adhesive film, as an important auxiliary material, plays a vital role. Here, Alster will give you a detailed introduction to the use and application of hot melt adhesive film for seamless underwear and the advantages of hot melt adhesive film in seamless underwear.

1. Basic overview of hot melt adhesive film

Hot melt adhesive film is a film made of polymer material, the main component of which is thermoplastic polymer. During the processing, this film will melt at a certain temperature to form an adhesive layer with adhesion. After cooling, the hot melt adhesive film will quickly solidify to form a strong adhesive layer. Its main features include excellent adhesion, high temperature resistance, easy operation and good flexibility.

2. Manufacturing process of seamless underwear

Traditional underwear manufacturing mostly uses sewing process, which is not only time-consuming and labor-intensive, but also may affect the comfort and appearance of wearing. The manufacturing process of seamless underwear avoids the discomfort and appearance defects caused by traditional sewing through a seamless weaving technology. This process usually uses a high-density circular loom or other weaving equipment, so that the entire structure of the underwear is integrated without any stitching or seams. This not only improves the comfort of the underwear, but also enhances its aesthetics.

3. The role of hot melt adhesive film in seamless underwear

Replacing traditional stitching lines

An important feature of seamless underwear is that there are no stitching lines. Hot melt adhesive film and web can be used as a substitute for stitching lines, bonding two or more fabric layers by melting at high temperature. This method allows each part of the underwear to fit together flatly, avoiding the marks and discomfort that may be caused by traditional stitching lines.

Enhance the comfort of underwear

The hot melt adhesive film has a soft property. After cooling and solidification, it can form a smooth adhesive layer, reducing the irritation of friction to the skin. This feature makes it more comfortable to wear seamless underwear and is not easy to cause allergic reactions to the skin.

Improve the durability of underwear

Because the adhesive layer formed by the hot melt adhesive film after cooling has strong adhesion and wear resistance, it can significantly improve the durability of the underwear. Even after multiple washing and wearing, the bonding effect of the hot melt adhesive film will not fail easily, and the overall structure of the underwear will not become loose.

Improve the aesthetics of underwear

Traditional sewing processes may leave obvious stitching lines or seams on the surface of underwear, while the use of hot melt adhesive film and web can ensure that the surface of the underwear is smooth and seamless. The seamless design for underwear not only improves the aesthetics of the underwear, but also better integrates with outerwear, avoiding wrinkles or prominent lines on the outerwear.

4. Material selection and process optimization of hot melt adhesive film

Material selection

The performance of hot melt adhesive film is closely related to the properties of the material used. Usually, hot melt adhesive film for seamless underwear will use thermoplastic polymers with excellent flexibility and heat resistance, such as polyester (PET), polyurethane (PU), etc. These materials can maintain good adhesion at high temperatures and form a stable adhesive layer after cooling.

Process optimization

During the production process, controlling the melting temperature and cooling rate of the hot melt adhesive film is the key. Too high a melting temperature may cause the adhesive layer to be too viscous, affecting the final effect; while too fast a cooling rate may result in loose bonding. Therefore, these parameters need to be precisely controlled to ensure that every part of the underwear is evenly bonded.

5. Future Development Trends

Application of Environmentally Friendly Materials

With the improvement of environmental awareness, more and more manufacturers have begun to pay attention to the environmental performance of hot melt adhesive films. In the future, more biodegradable and recyclable materials may be used in the production of hot melt adhesive films to reduce the impact on the environment.

Intelligent Production Technology

With the development of science and technology, intelligent production technology will likely be applied to the manufacture of seamless underwear. Precise control of the melting and cooling process of hot melt adhesive films by intelligent equipment can further improve underwear’s production efficiency and quality.

Personalized Customization

With the increase in consumer demand for personalization and customization, producing seamless underwear in the future may introduce more personalized design elements. Hot melt adhesive films can be adjusted according to different design requirements to achieve more diverse underwear styles and functions.

Applying hot melt adhesive films in manufacturing seamless underwear has significant advantages, including replacing traditional sutures, enhancing comfort, improving durability, and improving aesthetics. With the continuous development of science and technology and environmental protection requirements, the materials and processes of hot melt adhesive films will also be continuously optimized to meet the needs of the market and consumers. As an innovative representative of modern clothing, seamless underwear will continue to provide consumers with a more comfortable, beautiful, and environmentally friendly wearing experience through technical means such as hot-melt adhesive film.