In today’s globalized industrial landscape, materials that enhance performance while remaining eco-friendly are gaining significant traction. One such innovation is hot melt adhesive film – a versatile bonding material that has become essential across numerous sectors, including textiles, electronics, automotive, footwear, and medical manufacturing. As environmental regulations tighten and production efficiency becomes more critical, manufacturers are increasingly turning to solvent-free, thermally activated adhesives. This has propelled the demand for hot melt adhesive films on a global scale.

China has emerged as a manufacturing powerhouse for these adhesives due to its technological advancements, cost competitiveness, and robust export infrastructure. Numerous Hot Melt Adhesive Film Suppliers in China have gained international recognition for providing reliable, high-quality, and customizable solutions tailored to diverse applications.

This article provides an in-depth look into hot melt adhesive films, the reasons behind China’s dominance in this market, the criteria for choosing the right supplier, and introduces some of the notable players in the industry – including Alster, a trusted name among China-based hot melt adhesive film suppliers.

What is Hot Melt Adhesive Film?

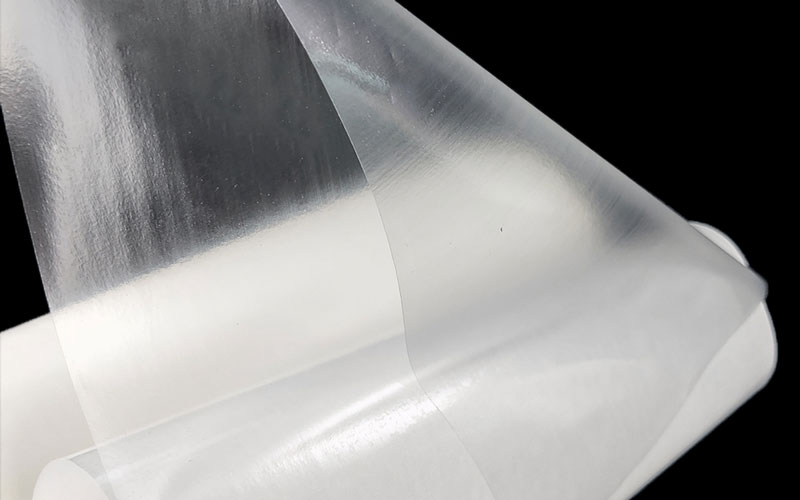

Hot melt adhesive film is a solid thermoplastic adhesive supplied in film form, designed to be activated by heat and pressure during bonding processes. Unlike traditional liquid adhesives, hot melt films are clean, easy to handle, solvent-free, and deliver precise application without excess waste.

Types of Hot Melt Adhesive Films:

EVA (Ethylene Vinyl Acetate) – Popular for textiles, especially embroidery patches, badges, and shoe linings.

TPU (Thermoplastic Polyurethane) – Flexible and elastic, commonly used in sportswear, electronics, and automotive interiors.

Polyester (PES) – Known for heat and chemical resistance, ideal for bonding technical fabrics and composite layers.

Polyamide (PA) – High-strength bonding and oil resistance, often used in the automotive and aerospace industries.

Polyolefin (PO) – Offers low processing temperatures and good barrier properties for packaging and medical use.

Advantages of Hot Melt Adhesive Film:

Eco-Friendly: No solvents or harmful emissions.

Clean Process: Solid form eliminates dripping and overspreading.

Consistent Bonding: Uniform layer thickness ensures repeatable results.

Multi-Substrate Compatibility: Works well with fabric, plastic, foam, leather, metal, and more.

Fast Production: No drying time required like in liquid adhesives.

The adaptability and performance of hot melt adhesive films make them the adhesive of choice for both manual and automated production lines, providing a seamless integration into modern manufacturing processes.

Why Source From China?

China is home to a vast number of Hot Melt Adhesive Film Suppliers, catering to both domestic and international markets. But what makes China such a compelling hub for sourcing?

1. Cost Advantage

One of the primary reasons companies source from China is the cost-effectiveness. Due to economies of scale, availability of raw materials, and efficient labor, Chinese suppliers can offer competitive pricing without compromising quality.

2. Technological Maturity

Chinese manufacturers have made significant advancements in polymer chemistry and film extrusion technologies. Many suppliers now offer multilayer composite films, breathable structures, and high-transparency variants. Some even specialize in biodegradable or recyclable hot melt films.

3. Integrated Supply Chain

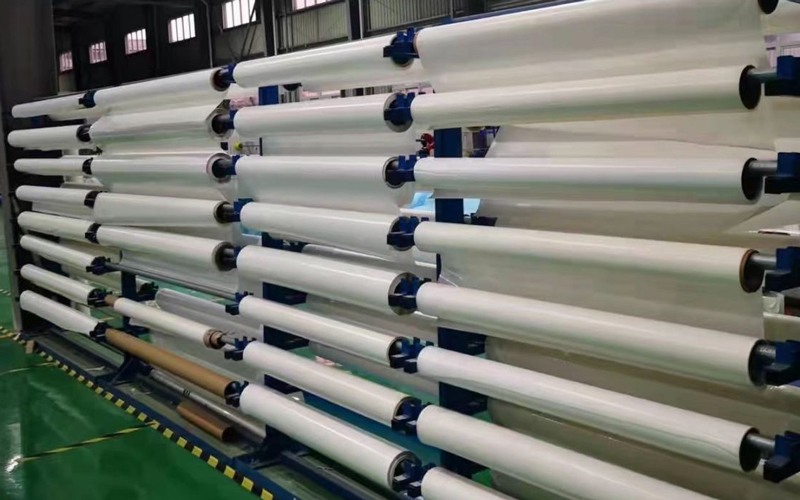

From polymer resin production to extrusion, coating, lamination, slitting, and packaging, China has a complete supply chain. This integration reduces lead times and ensures better quality control at each stage.

4. Export Capabilities and Certifications

Leading Chinese Hot Melt Adhesive Film Suppliers are equipped with international certifications such as ISO 9001, OEKO-TEX, RoHS, and REACH. These credentials help facilitate global trade, especially in markets with stringent safety standards.

5. Customization and Innovation

Suppliers in China are increasingly R&D-driven, offering custom thickness, width, melting temperature ranges, and even anti-yellowing or water-washable versions tailored to specific customer needs.

Key Criteria for Selecting Hot Melt Adhesive Film Suppliers in China

Finding the right supplier is more than just a price comparison. Here are some vital factors to consider:

1. Production Capacity

Ensure the supplier has the ability to meet your demand volumes, both during regular production and peak seasons. Suppliers with multiple production lines and automated systems are more reliable partners.

2. Technical Support and R&D Capabilities

Can they offer formulation adjustments based on your application needs? Do they provide guidance on pressing conditions (temperature, time, pressure)? A good supplier should have a professional R&D and customer service team.

3. Quality Control System

Look for consistency. Ask about their quality control measures – from incoming raw materials to finished product testing. Reputable suppliers use equipment such as DSC testers, peel strength testers, and thermal analysis labs.

4. International Trade Experience

Check if the supplier has a dedicated export department. International trade experience helps avoid miscommunication, ensures proper documentation, and guarantees better logistic coordination.

5. Reputation and Case Studies

Request reference clients or industry case studies. If they’ve worked with globally recognized apparel brands or electronics manufacturers, that’s a good sign of reliability.

Introducing Alster

Among China’s reliable Hot Melt Adhesive Film Suppliers, Alster stands out for its blend of affordability, innovation, and service. With years of manufacturing experience, Alster provides a full range of adhesive films – from TPU for sports textiles to PES films for automotive and composite materials.

Alster invests in environmentally friendly production methods and constantly develops films for niche applications such as washable garment labels and low-temperature bonding solutions. Whether you’re in need of high-volume production or small-batch customization, Alster offers flexible cooperation models for global partners.

Market Trends and Future Outlook

As sustainability and smart manufacturing continue to dominate industrial priorities, the future of hot melt adhesive films looks promising.

1. Sustainability Focus

Demand is rising for films made from biodegradable polymers or recycled materials. Water-based coatings and solvent-free formulations are already standard for many Chinese manufacturers.

2. Smart Functionality

Films with added functionality – such as thermal conductivity, electrical insulation, or antimicrobial properties – are under rapid development. These are particularly attractive for electronics, medical wearables, and home appliances.

3. Automation Compatibility

More manufacturers are investing in films suitable for automatic lamination lines and robotic applications, offering consistent behavior and reduced process downtime.

4. Global Expansion

Chinese Hot Melt Adhesive Film Suppliers are actively participating in global expos and establishing overseas warehouses or distributor networks. With improved logistics and multilingual support, they are becoming more accessible to buyers in Europe, North America, and Southeast Asia.

Alster is at the forefront of these trends, expanding their R&D on bio-based adhesive films and forging partnerships in North America and the EU. Their adaptability ensures that customers not only get products that work today, but also solutions that meet tomorrow’s needs.

How to Work Effectively With Chinese Hot Melt Adhesive Film Suppliers

To ensure a smooth partnership, consider the following tips:

1. Define Clear Technical Specifications

Provide detailed requirements such as thickness, melting range, bonding substrates, and application methods. This helps suppliers like Alster recommend the most suitable film.

2. Request Samples and Conduct Trials

Before placing large orders, test multiple samples under production conditions. Reliable suppliers will provide test reports, bonding strength data, and technical guidance.

3. Establish a Quality Agreement

Include standards for visual defects, peel strength, aging resistance, and packaging requirements. A clear QC protocol builds mutual trust.

4. Communicate Regularly

Set fixed points of contact and schedule regular video meetings or factory audits (on-site or virtual). This ensures alignment during production and logistics planning.

5. Consider Long-Term Collaboration

Many suppliers, including Alster, offer better pricing, priority service, and technical co-development to long-term partners. Building trust over time leads to mutual growth.

Conclusion

Hot melt adhesive films are transforming the way industries bond materials, offering cleaner, faster, and more sustainable solutions. As demand continues to grow globally, Hot Melt Adhesive Film Suppliers in China are uniquely positioned to meet this need – with their vast production capabilities, technical innovation, and competitive pricing.

Choosing the right partner is critical. Suppliers like Alster combine technical expertise, customization flexibility, and strong export support to deliver reliable adhesive film solutions to clients worldwide.

Whether you’re sourcing for garment lamination, electronic component assembly, or automotive interior bonding, building a partnership with trusted Hot Melt Adhesive Film Suppliers from China is a strategic move for quality and cost-efficiency.