In the field of adhesives, two popular types are often used for various industrial applications: Hot Melt Adhesive Film and Hot Melt Adhesive Web. While both belong to the same category of thermoplastic adhesives, they have distinct characteristics, advantages, and uses. This article will provide an in-depth comparison between the two, examining their differences, benefits, and the types of applications they are most suited for.

1. Introduction to Hot Melt Adhesives

Hot melt adhesives are thermoplastic materials that become liquid when heated and solidify when cooled. They are commonly used in bonding applications because of their quick-setting properties and ability to form strong, durable bonds. These adhesives can come in the form of various products, including films and webs, each designed to meet specific requirements depending on the task at hand.

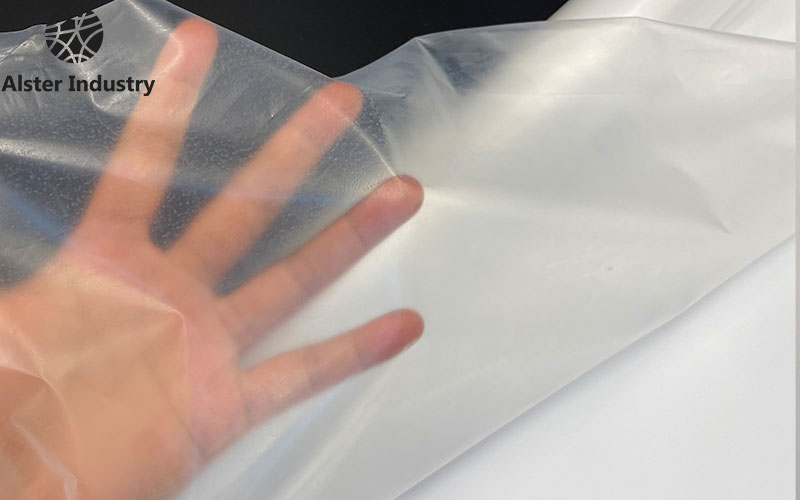

- Hot Melt Adhesive Film: This form of adhesive comes in a solid, thin sheet that melts when heated. It is ideal for applications that require a uniform adhesive layer.

- Hot Melt Adhesive Web: Typically applied as a non-woven, porous sheet or mesh, this form of adhesive is more flexible and is commonly used in applications where higher bond strength and better coverage are needed over irregular surfaces.

2. Manufacturing Process and Structure

Hot Melt Adhesive Film is produced by extruding or casting the adhesive material into thin sheets, which are then cooled and cut to size. The adhesive film maintains a consistent thickness and is often used in applications where the adhesive needs to be uniformly distributed.

On the other hand, Hot Melt Adhesive Web is typically made by melting the adhesive and spreading it over a substrate, creating a thin, porous mesh-like structure. This web is often pre-applied to one of the surfaces and can be activated with heat during the bonding process.

The key difference in manufacturing is that the film is smooth and uniform, whereas the web is more flexible and non-woven, offering better coverage on uneven surfaces.

3. Application Methods

Hot Melt Adhesive Film is generally used in automated bonding processes. The film can be applied using roll-to-roll systems or pre-applied to one surface, and it is then activated by heat. The film’s thin consistency allows it to provide an even adhesive layer, making it ideal for delicate or fine applications.

Hot Melt Adhesive Web is applied in a more versatile manner. It can be pre-applied to one surface or applied directly to both parts of the assembly. When activated by heat, the adhesive web melts and bonds the surfaces together. The web is often used for more complex or irregular-shaped surfaces where a more flexible adhesive bond is required.

4. Advantages of Hot Melt Adhesive Film

- Uniformity: Hot Melt Adhesive Film provides a consistent thickness of adhesive, which is beneficial when uniform coverage is required.

- Clean Application: The solid film is easy to handle and results in minimal mess, as it does not leave excess adhesive.

- Precision: The film can be applied in precise amounts, making it ideal for applications that require accurate adhesive placement.

5. Advantages of Hot Melt Adhesive Web

- Flexibility: Hot Melt Adhesive Web is more adaptable to various surface types, making it suitable for bonding uneven or porous surfaces.

- Faster Setup: Since the web can be pre-applied to one surface, setup times are reduced, improving overall production efficiency.

- Higher Bond Strength: The web’s non-woven structure often leads to stronger adhesion, particularly on textured or non-flat surfaces.

6. Performance Comparison

Temperature Resistance: Both hot melt adhesive film and web have excellent heat resistance once cured. However, web adhesives tend to perform better in applications where flexibility and adaptability to high-heat environments are required.

Bonding Speed: Hot Melt Adhesive Film typically sets quickly due to its thin, uniform nature. However, Hot Melt Adhesive Web may take slightly longer to set, depending on the material and thickness.

Environmental Resistance: While both types can be formulated for specific environmental resistance, hot melt adhesive web often provides better performance in demanding outdoor or weather-exposed conditions due to its enhanced flexibility and superior bonding strength.

7. Hot Melt Adhesive Film VS Web: Common Applications

Hot Melt Adhesive Film is commonly used in the following industries:

- Automotive: Bonding trim components, seals, and insulation materials.

- Electronics: For bonding components in delicate assemblies.

- Packaging: In processes where thin and uniform adhesive layers are required, such as in packaging cartons, labels, and protective packaging.

Hot Melt Adhesive Web finds applications in:

- Textiles: For bonding fabrics and garments, especially in nonwoven textiles.

- Furniture Manufacturing: In the assembly of upholstery, where flexibility is needed to accommodate different shapes and surfaces.

- Construction: For bonding insulation materials, flooring, and roofing elements, where a more robust and flexible bond is needed.

8. Cost Considerations

Generally speaking, Hot Melt Adhesive Film can be more expensive than the adhesive web due to its more specialized production process. However, because of its uniform application and precision, it can lead to lower costs in production by reducing wastage.

Hot Melt Adhesive Web is typically less expensive per unit but may require more precise application and additional equipment, which can increase overall production costs. However, its superior flexibility and bond strength can offset these costs, particularly in high-volume manufacturing settings.

9. Environmental Impact and Sustainability

As with most adhesives, both hot melt films and webs have a limited environmental impact. However, the production of these materials can lead to waste, and recycling can be a challenge. Some manufacturers are working on developing more sustainable hot melt adhesives, including bio-based options for both films and webs. The environmental footprint of each will depend on the formulation and the production processes used.

10. Conclusion

Both Hot Melt Adhesive Film and Hot Melt Adhesive Web have their unique advantages, and the choice between the two depends largely on the application requirements. For precise, clean, and uniform adhesive layers, film is the preferred choice, especially in delicate and small-scale applications. On the other hand, webs are ideal for applications that demand more flexibility, higher bond strength, and the ability to bond irregular or porous surfaces.

Choosing the right adhesive type can significantly impact the efficiency and durability of the bonding process. As always, the selection should be made based on the specific demands of the project, including materials, surface types, environmental conditions, and cost-effectiveness.