Hot Melt Adhesive Sheets

Hot Melt Adhesive Sheets are high-performance adhesive materials carefully developed and manufactured by the Alster brand, specially designed for high-strength bonding needs in industrial applications. The product is a sheet-like solid that melts quickly when heated to a certain temperature, then cools and solidifies to form a long-lasting and stable bonding effect. Welcome to contact us for product quotes!

- EVA (Ethylene-Vinyl Acetate) Hot Melt Adhesive Sheets

- PO (Polyolefin) Hot Melt Adhesive Sheets

- TPU (Thermoplastic Polyurethane) Hot Melt Adhesive Sheets

- PES (Polyester) Hot Melt Adhesives

Types of Hot Melt Adhesive Sheets

According to different materials, hot melt adhesive sheets can be divided into many types (TPU, EVA, PES, PO, etc.)

Thermoplastic polyurethane (TPU) hot melt adhesive sheet has excellent wear resistance and elasticity, suitable for high-strength, wear-resistant applications such as sports shoes and automotive accessories, ensuring long-term reliability.

Thermoplastic elastomer (TPE) hot melt adhesive sheet combines the advantages of rubber and plastic, has good flexibility and low-temperature performance, and is suitable for diversified applications such as medical devices, consumer electronics and toys.

Good flexibility, suitable for scenarios requiring elasticity, such as textile and footwear manufacturing. Alster uses high-quality EVA raw materials to ensure the best bonding effect.

With excellent heat resistance and mechanical strength, it is widely used in electronic components, automotive interior parts and other fields with high temperature and bonding strength requirements.

With extremely strong moisture resistance and high temperature resistance, it is especially suitable for applications that require water resistance and high temperature stability, such as home appliance packaging, electronic circuit protection, etc.

It has a low melting point and is suitable for general applications, especially for packaging and laminating materials that do not require high thermal stability in the packaging industry.

Hot Melt Adhesive Sheet Product Features

Excellent bonding strength

After heating and melting, hot melt adhesive sheets can form strong and stable bonds with a variety of substrates such as metals, plastics, textiles, and foam materials. They are particularly suitable for industrial scenarios with high requirements for bonding strength.

Easy operation

Alster's hot melt adhesive sheets are easy to process and can be quickly melted and bonded without complex equipment, which greatly improves production efficiency, especially suitable for mass production scenarios.

Environmentally friendly and solvent-free

The hot melt adhesive sheets produced by Alster do not contain harmful solvents, are non-toxic and odorless during production and use, meet environmental protection standards, and are the preferred adhesive material for green manufacturing.

Diverse specifications

Alster can customize hot melt adhesive sheets of different thicknesses and sizes according to customer needs to meet the needs of different application fields and provide customers with flexible solutions.

Excellent water and moisture resistance

Hot melt sheet has good water and moisture resistance, which can effectively prevent moisture penetration and ensure that the bonding part can still maintain strength and stability in a humid environment. Suitable for outdoor applications and industrial use .

Weather resistance and durability

Good anti-aging, temperature resistance, and chemical corrosion resistance. It can maintain excellent performance even in extreme environments, ensuring long-term stability and reliability.

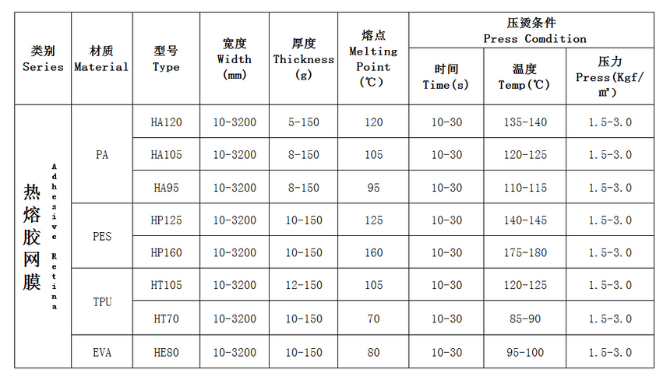

Specifications of Hot Melt Adhesive Sheets

Differences from hot melt adhesive film

Morphology and thickness

- Hot melt adhesive sheet: The thickness is relatively large, usually between 0.05mm and 2mm, suitable for bonding thick and heavy materials.

- Hot melt adhesive film: The thickness is thinner, usually between 0.01mm and 0.2mm, suitable for bonding thin and light materials or precision parts.

Application areas

- Hot melt adhesive sheet: mostly used in bonding scenarios that require strength and thickness, such as soles, foam materials, furniture manufacturing, etc.

- Hot melt adhesive film: suitable for delicate bonding operations, especially in fields with high requirements such as seamless clothing and electronic products.

Operation method

- Hot melt adhesive sheet: requires higher temperature and longer heating time, usually operated by hot press or lamination equipment.

- Hot melt adhesive film: due to its thin thickness, fast melting speed and more flexible operation, it is suitable for use in delicate equipment or small batch processing.

Product use areas

- Seamless clothing manufacturing: Alster’s hot melt adhesive sheet is widely used in the field of seamless clothing, especially for bonding uppers and soles, and splicing and integration of seamless underwear, providing high-strength, seamless bonding effects.

- Electronic product manufacturing: used for packaging and sealing of electronic components to ensure that components remain stable in high temperature or humid environments.

- Automotive industry: In the bonding of automotive interior parts, headlights, and roof materials, Alster hot melt adhesive sheets perform well and can meet the stringent requirements for strength, durability, and heat resistance in the automotive industry.

- Furniture manufacturing: widely used in foam cushions, wood bonding and the manufacture of upholstered furniture, providing a long-lasting bonding solution for modern furniture.

Product production process

- Raw material selection: Alster strictly selects high-quality hot melt adhesive raw materials such as EVA, PA, PES, etc. to ensure the high quality and stability of each batch of films.

- Melt extrusion: The hot melt adhesive raw materials are heated and melted through high-precision extrusion equipment and then extruded into sheets.

- Cooling and shaping: The film is solidified and shaped through cooling equipment to ensure the dimensional accuracy and thickness uniformity of the sheet.

- Cutting and packaging: The film is accurately cut and packaged according to customer needs to ensure that each film meets the customer’s specific requirements.

- Quality inspection and packaging: Each batch of products undergoes strict quality inspection to ensure that the hot melt adhesive sheets shipped from the factory are free of defects, and appropriate protective packaging is used to ensure that they are not damaged during transportation.

Alster's professional advantages

Technological leadership

Alster relies on a number of independent technologies and patents in the field of hot melt adhesives to ensure that each batch of products meets the highest standards in the industry, especially in seamless clothing and automotive industry bonding.

Strict quality control

From raw material selection to every link in the production process, Alster conducts strict quality control to ensure that each hot melt adhesive sheet has excellent bonding performance and stability.

Customized service

Alster can provide tailor-made solutions according to the specific needs of customers. From thickness, size to film material, it can be flexibly adjusted to ensure that the special needs of different industries are met.

Other Related Products

Hot Melt Glue Sheet

Hot melt glue sheet (hot melt adhesive film) is an...

Read MoreSeamless Underwear Machine for Sale

Seamless Underwear Machine for Sale Alster®️ is a professional seamless...

Read MoreOverlapping Sewing Machine for Sale

Overlapping Sewing Machine for Sale Alster®️ is a professional seamless...

Read MoreSilicone Coating Machine for Sale

Silicone Coating Machine for Sale Alster®️ is your trusted silicone...

Read More