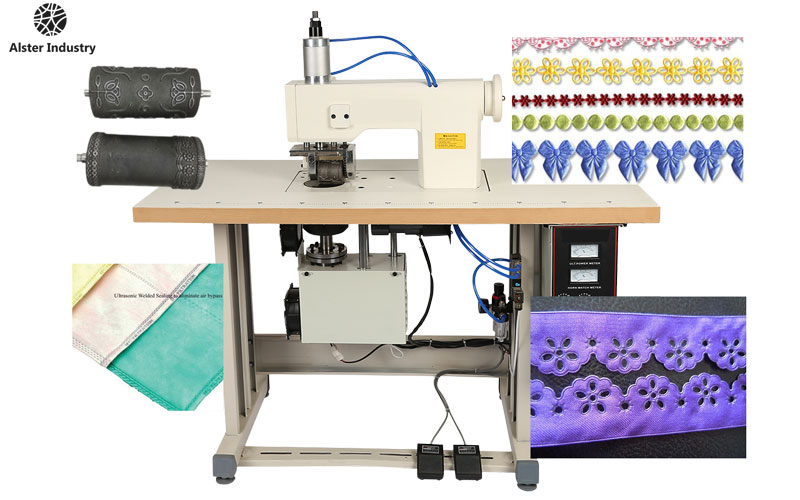

The ultrasonic lace sewing machine is an innovative technology in the modern textile industry. It is widely used in the textile, clothing, non-woven fabrics and other industries for the processing of fine decorations such as lace and lace. This machine is different from the traditional mechanical sewing machine. It uses the principle of ultrasonic vibration to connect or sew materials through high-frequency sound waves, so as to achieve efficient, fine and seamless effects. This article will discuss in detail the working principle, characteristics and applications of ultrasonic lace sewing machines.

1. Working principle of ultrasonic lace sewing machine

The working principle of ultrasonic lace sewing machine is based on ultrasonic technology. Ultrasonic waves are sound waves with a frequency higher than the hearing range of the human ear, usually defined as sound waves above 20kHz. In the ultrasonic lace sewing machine, the ultrasonic oscillator converts electrical energy into mechanical vibrations. This vibration can produce high-frequency tiny fluctuations on the surface of the material, so that the binding force between the material molecules changes, thereby achieving bonding or welding.

- Ultrasonic generator: The core component of the ultrasonic lace sewing machine is the ultrasonic generator, which converts electrical energy into high-frequency ultrasonic signals. The ultrasonic frequency is usually between 20-40kHz, and the ultrasonic energy is transmitted to the sewing head through the transducer.

- Transducer and welding head: The transducer converts the ultrasonic signal into mechanical vibration and transmits this vibration to the welding head. The welding head is usually designed with precision to apply the vibration directly to the material to be processed. During this process, the vibration of the ultrasonic lace sewing machine will cause the surface temperature of the material to rise sharply. After reaching the melting point, the molecules of the material will be reorganized, and finally it will be firmly connected or sewn.

- Welding and bonding of materials: On the surface of the material, especially at the contact point of non-woven fabrics, films and textiles, the vibration energy of the ultrasonic wave can effectively melt the fiber or thermoplastic part of the material to form a welding point. This method is different from traditional sewing. It not only avoids the operation of threading the needle, but also completes the work in a short time.

2. Ultrasonic lace sewing machine working video

By understanding the working principle of the machine, I believe you have a basic understanding of the ultrasonic lace sewing machine. Here is an operation video. Through the following video, you can understand more clearly how the ultrasonic lace sewing machine works:

3. Characteristics of ultrasonic lace sewing machine

- High efficiency: Traditional sewing requires multiple steps such as threading and knotting, while the ultrasonic lace sewing machine directly welds on the surface of the material through high-frequency ultrasound, eliminating many tedious processes in the sewing process. This greatly improves work efficiency and is particularly suitable for large-scale production.

- Seamless connection: The ultrasonic lace sewing machine can achieve seamless connection on the surface of the material, avoiding the needle eye marks and thread marks caused by traditional sewing. In addition, ultrasonic sewing can be operated on a variety of different materials, including non-woven fabrics, plastic films, thin textiles, etc., which greatly expands its application range.

- Fine and beautiful: Traditional sewing machines are prone to unevenness or deformation when processing delicate lace and lace. The ultrasonic lace sewing machine can perform fine processing within a small range through precise vibration control, thereby ensuring the perfect shape and uniformity of the lace, achieving a more refined and beautiful effect.

- Environmental protection: Ultrasonic technology does not require the use of traditional wires and needles, nor does it rely on a large amount of chemical glue or adhesive, so it is more environmentally friendly. This not only reduces the waste of resources in the production process, but also reduces pollution to the environment.

- High safety: Since ultrasonic sewing is performed through sound wave vibration, there will be no mechanical needle passing through the material during operation like a traditional sewing machine, thus reducing the risk of injury to the operator.

4. Application fields of ultrasonic lace sewing machine

- Textile and clothing industry: Ultrasonic lace sewing machines are widely used in textile and clothing industries for detail processing such as lace, lace, and edge decoration. Especially for the production of fine crafts such as high-end clothing, underwear, and wedding dresses, ultrasonic technology can provide higher processing accuracy and visual effects.

- Non-woven fabric industry: In the production of non-woven fabrics, ultrasonic lace sewing machines are used for edge sealing, stitching and other operations of non-woven fabrics. This technology can effectively prevent the de-threading and wear of the edge of non-woven fabrics, thereby extending the service life of the product.

- Plastic film processing: Ultrasonic lace sewing machines have unique advantages in plastic film processing. It can efficiently weld plastic films, avoid problems such as uneven temperature that may occur in traditional heat sealing processes, and ensure the firmness and beauty of the welded parts.

- Medical and sanitary products: In the production of medical supplies, ultrasonic technology is used to connect non-woven materials, especially in the production of medical and sanitary products such as masks, surgical gowns, and isolation gowns, which can achieve efficient and pollution-free processing.

Summary

Ultrasonic lace sewing machines achieve seamless and fine material connections through high-frequency vibrations, and have efficiency, precision and environmental protection that traditional sewing machines cannot match. With the development of science and technology, the application fields of ultrasonic lace sewing machines are constantly expanding, especially in the textile, clothing, non-woven fabrics and medical and health industries, playing an increasingly important role. In the future, with the continuous innovation and improvement of technology, ultrasonic lace sewing machines are expected to show their talents in more fields and promote the upgrading and development of related industries.