As the underwear market’s requirements for comfort, functionality and aesthetics continue to increase, traditional bra making processes are gradually being replaced by efficient and precise seamless technology. Seamless bras not only provide higher comfort, but also ensure perfect fit and seamless effects. In this process, the Alster roller seamless hem machine, as an innovative device, provides great help for the production of seamless bras. This article will introduce in detail how to use the Alster roller seamless hem machine to make seamless bras, helping manufacturers improve production efficiency and product quality.

1. The basic concept of seamless bras

Seamless bras refer to a type of underwear processed by special seamless technology. Unlike traditional seamed bras, seamless bras use high-end knitting and hot pressing technology, so that the underwear has no obvious seams when worn, avoiding the pressure of the seams on the skin, and also improving the beauty and comfort of the bra. Seamless bras are widely used in daily wear, sports bras, and shaping bras.

2. The role of the seamless hem machine

Alster roller seamless hem machine is an efficient equipment for seamless clothing hem processing, especially for bra hem processing. When making seamless bras, the following key functions can be achieved by using this equipment:

- Precise hem processing: Through seamless heat pressing technology, Alster seamless hem machine can accurately fold, shape and press the hem of the bra to ensure that the hem is flat, wrinkle-free, without any seams, and fits the skin perfectly.

- Efficient production: Compared with traditional sewing methods, seamless hem machines greatly improve production efficiency. The operator only needs to simply set the machine parameters, and the machine can automatically complete the folding, heating and pressing process of the hem, greatly saving labor and time.

- Reduce fabric waste: Seamless hem technology avoids fabric waste caused by traditional sewing by precisely controlling heat pressing and folding width, and can better utilize materials and reduce production costs.

3. How to use Alster roller seamless hem machine to make seamless bras

The process of making seamless bras is relatively complicated and involves multiple links, including material preparation, machine adjustment, production operation, etc. Here are the basic steps to make a seamless bra using the Alster Roller Hem Machine:

Choosing the right fabric

Seamless bras are generally made of soft, stretchy knitted fabrics such as nylon and spandex. These fabrics provide good stretch and comfort, and can also work with the seamless hem machine’s heat pressing technology to form a solid hem effect.

Adjusting the Alster Roller Hem Machine

Before production, the machine’s temperature, pressure and fold width need to be adjusted according to the type and thickness of the fabric. The Alster Seamless Hem Machine is equipped with an advanced temperature control system that can accurately control the heat pressing temperature and time according to the needs of different fabrics, thereby ensuring the perfect folding and shaping of the bra hem.

Setting the Seamless Bra Mold

Seamless bras are designed to work with precise molds that help the machine better control the shape and size of the bra during the production process. The Alster Seamless Hem Machine can be customized according to different mold requirements to ensure that the size and shape of each bra are up to standard.

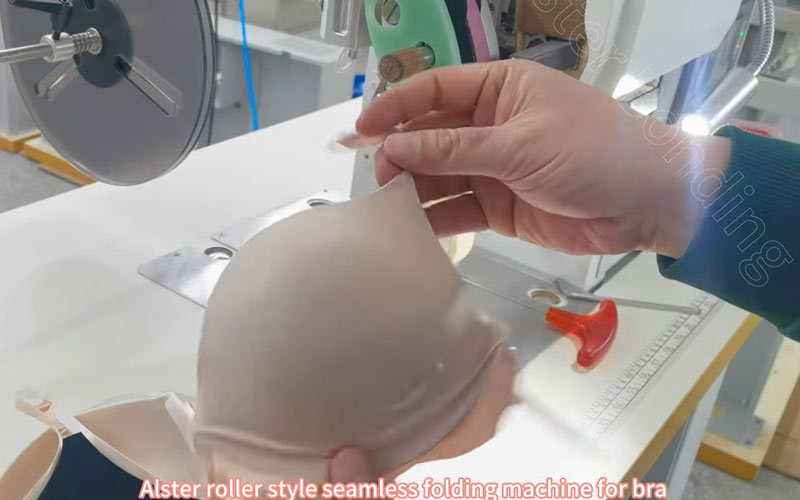

Heat pressing and hem folding

Before putting the bra fabric into the machine, the operator needs to ensure that the fabric is flat and the fold position is accurate. The Alster roller-type seamless hem machine folds and fixes the hem of the fabric through heat pressing technology. Through the continuous rolling of the heated roller, the edge of the hem of the fabric is firmly pressed, thus avoiding the difficulties of traditional sewing.

Post-completion inspection

After completing the heat pressing and hem folding, the operator needs to check the quality of each seamless bra to ensure that the hem is flat, wrinkle-free, and has not fallen off or deformed. The Alster seamless hem machine can maintain high-precision heat pressing effects to ensure the high quality of each product.

Post-processing

Although most of the work can be done using a seamless hem machine, other details may need to be processed in some specially designed bras, such as the installation of elastic bands and shoulder strap adjustment. These can be completed with other auxiliary equipment to ensure the perfect embodiment of seamless bras in terms of comfort and functionality.

4. Advantages of the Alster roller-type seamless hem machine

- Simple operation: The Alster seamless hem machine is humanized in design, and the operation interface is simple and easy to understand. Employees can start operating after a short period of training, which greatly reduces the possibility of manual intervention and operating errors.

- High precision guarantee: The machine adopts a high-precision temperature control system and folding control technology, which can achieve high-quality seamless folding during the production process, ensuring that every seamless bra meets the standards.

- Energy saving and environmental protection: Compared with the traditional sewing process, the Alster seamless hem machine is more energy-efficient, which can effectively reduce energy consumption in the production process and reduce production costs.

- Diversified applications: In addition to bras, the Alster seamless hem machine is also suitable for the hem processing of various seamless underwear, sportswear, shaping clothes and other products. It is an ideal equipment for producing high-quality seamless clothing.

Using the Alster roller seamless hem machine to make seamless bras not only improves production efficiency, but also ensures the high quality and comfort of the products. With the continuous development of seamless technology, this advanced equipment will be more and more widely used in underwear production, driving the industry towards a more intelligent, refined and efficient direction. Both manufacturers and consumers will benefit from this innovative technology and enjoy more comfortable and fashionable seamless bras.