Hot melt tape is widely used in the hemming process of the garment industry due to its excellent bonding properties and easy operation. By properly applying hot melt tape, the efficiency of garment processing can be significantly improved while ensuring the quality and aesthetics of the finished product. This article will detail how to use hot melt adhesive film for hemming in garment industry, including the equipment and materials required, specific steps, and precautions.

1. Required Equipment and Materials

Before using hot melt tape for hemming, you need to prepare the following equipment and materials:

- Hot Melt Film: Choose a hot melt tape that is appropriate for the fabric you are using.

- Clothing edging materials: such as cotton, polyester, nylon and other textiles.

- Heating equipment: such as a heat press or iron.

- Release paper or silicone pad (if necessary): used to protect the surface of the fabric.

- Scissors: Used to cut hot melt tape and fabric.

2. Preparation

Before formal operation, the fabric and work area need to be fully prepared:

- Clean the fabric: Make sure the edges of the fabric to be hemmed are clean and free of dust and debris that may affect the bonding process.

- Cutting hot melt tape: Accurately cut the hot melt tape according to the required edge length. When cutting, leave a little margin to prevent it from being too short.

3. Hemming operation steps

The following is the specific operation process of using hot melt tape for hemming:

Positioning tape

Place the cut hot melt tape on the edge of the fabric that needs to be hemmed. Make sure the adhesive side of the hot melt tape is facing the fabric and completely covers the width of the hemming area.

Heating Bonding

Use a heat press or iron to apply heat and pressure to the tape. The heat press temperature and time should be adjusted according to the manufacturer’s instructions for the hot melt tape. Generally speaking, the temperature ranges from 120°C to 180°C and the time is 5-10 seconds.

Cooling and fixing

After heating, keep the fabric and tape relatively still and wait for them to cool and set. If desired, cover the fabric with release paper or a silicone mat during the cooling period to prevent the surface from sticking.

Trim excess

After cooling, use scissors to trim the excess hot melt tape and fabric edges to ensure a neat and beautiful hem.

Check the bonding effect

Gently pull on the binding fabric to check that the bond is secure. If loose areas are found, reheat and press.

Final finishing

After the hemming is completed, you can press lightly on the hemmed area again to ensure that the surface is flat and wrinkle-free.

Precautions

In actual operation, the following points should be noted:

Temperature control

The operating temperature and time may vary for different hot melt tapes. Follow the manufacturer’s instructions for setting the temperature and how long to apply pressure to avoid damaging the fabric or tape due to excessive temperatures.

Fabric selection

Choose the right hot melt tape for different types of fabrics. For example, stretchy fabrics require a hot melt tape with elasticity, while thin fabrics require a tape with a lower melting point.

Combination

If you need to bond two layers of fabric together, you can sandwich hot melt tape between the fabrics and bond them together through heat and pressure.

Test Operation

Before formal processing, it is recommended to conduct trial operations on scrap materials to familiarize yourself with the process and adjust equipment parameters.

Advantages of hot melt adhesive films

Hot melt tape has the following advantages when used for clothing hemming:

- Easy to operate: no sewing or sewing is required, only heat and pressure are required to complete the bonding.

- Strong aesthetics: The hemming effect is smooth and seamless, avoiding the needle holes or thread ends that may occur in traditional sewing processes.

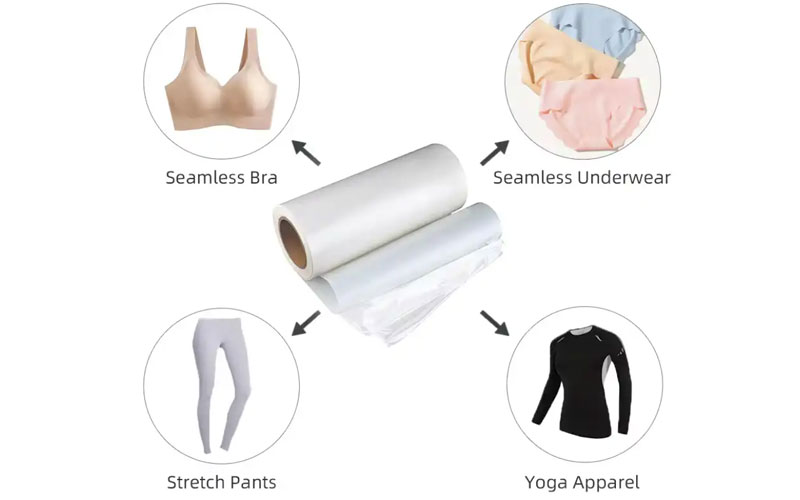

- Wide applicability: Suitable for processing clothing of various materials and uses, such as seamless underwear, sportswear, home clothes, etc.

- High environmental protection: Many hot melt tapes have environmental protection characteristics such as solvent-free and odorless, which meet the requirements of modern green production.

Conclusion

The emergence of hot-melt tape provides an efficient and environmentally friendly solution for the hemming process in the clothing industry. During use, you only need to master the key points of equipment operation and choose the appropriate hot-melt tape based on the characteristics of the fabric to easily achieve a firm and beautiful edging effect. At the same time, practice and experience are the key to improving processing quality. By conducting sufficient testing before operation, potential problems in processing can be effectively avoided, thus ensuring the high quality of the final product. Want to get more information about the hot melt adhesive film from Alster? Welcome to contact us now!