In the modern clothing manufacturing industry, hot melt adhesive film, as an innovative material, is gradually replacing traditional needle and thread sewing technology. It can make clothing fit the curves of the human body better and achieve a truly “seamless” effect. Especially in the production of seamless shirts, the application of hot melt adhesive film not only simplifies the production process, but also greatly improves the wearing comfort and quality of the finished product.

1. Specific application of hot melt adhesive film on seamless shirts

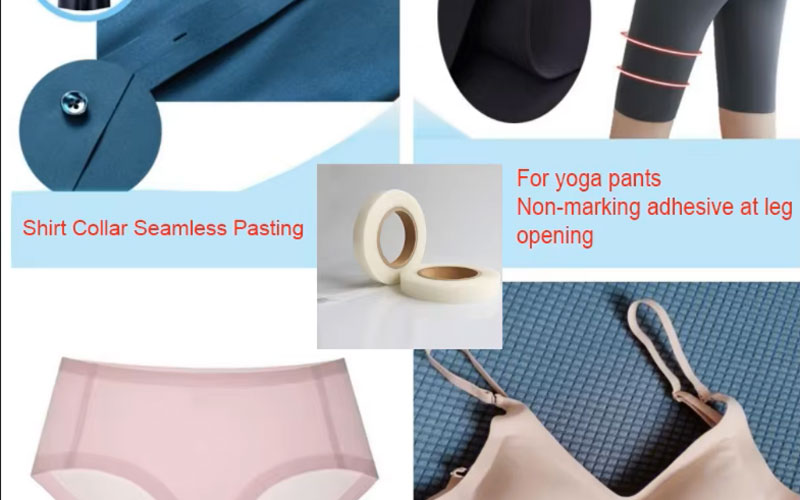

Seamless shirts use hot melt adhesive film seamless bonding technology to replace the traditional sewing process, making the production operation easier and significantly improving production efficiency. The following are the main application scenarios of hot melt adhesive film in different parts of seamless shirts:

Neck bonding

When it comes to collar treatment, hot melt adhesive film can achieve a smooth and seamless bonding effect. Through the hot-melt adhesive film, the edge of the collar will not curl or shrink, and the finished product will have a clean, crisp and stylish texture.

Binding on cuffs and hem

The cuffs and hem are bonded with hot-melt adhesive film to achieve an exquisite edging effect. After many washes, the bonded areas remain strong and are resistant to wear and deformation, making them more comfortable and natural to wear.

Lapel bonding

The shirt’s lapel is made with a seamless bonding process, making the surface smoother and more fitted, softer to the touch, and visually presenting a three-dimensional effect. At the same time, the bonding area is strong and washable, and is not prone to debonding.

Seam bonding

The use of hot melt adhesive film at the joints and seams of fabrics can eliminate the pinhole problem in traditional sewing processes and achieve seamless edge processing. The finished product is lighter to wear, fits closely without feeling restrictive, and is significantly more comfortable.

Pocket bonding

The seamless bonding process of the hot-melt adhesive film can make the shirt pockets fit better with the main body of the garment, which not only looks invisible and high-end, but is also more practical.

2. Production process of seamless shirts

The production of seamless shirts uses laser cutting and seamless bonding technology, which effectively replaces the traditional sewing process, making the operation process simpler and more efficient. The promotion of this technology not only saves production time, but also improves the overall quality of garments.

Common seamless bonding equipment includes irons, presses and dedicated seamless hemming machines. Different devices have their own characteristics:

- Iron operation: suitable for beginners, easy and flexible operation, suitable for small batches and simple seamless bonding tasks.

- Seamless folding machine: The bonding effect is more uniform and smooth, especially suitable for processing complex details, and more efficient in large-scale production.

Here are the specific steps for using an iron to perform a seamless hem operation:

Positioning hot melt adhesive film

Place the cut hot melt adhesive film on the edge of the fabric and press lightly with an iron for 3-4 seconds to fix the film.

Remove the release paper

After the film is fixed, carefully tear off the release paper on the surface and prepare for the next step of bonding.

Glue hem

After folding the fabric in half, press it with an iron for 8-15 seconds to ensure that the film is fully bonded. When finished, the edges are nice and clean.

3. Advantages of hot melt adhesive film seamless process

Hot melt adhesive film brings many significant advantages in the production process of seamless shirts:

Significantly improved wearing comfort

Seamless bonding technology eliminates the friction caused by stitches in traditional sewing, making clothes more close-fitting and softer, providing higher wearing comfort.

Higher quality appearance

Seamless bonding makes the lines of clothing more smooth and three-dimensional, and the overall look more upscale, catering to consumers’ pursuit of high-quality clothing.

Improved production efficiency

The seamless bonding process reduces tedious sewing steps, greatly shortens production time and meets the needs of fast delivery.

Environmental protection and durability

Hot melt adhesive film is environmentally friendly and does not require the use of excess chemical additives during the production process. At the same time, the bonding effect is durable and not easy to debond.

4. The future of seamless shirts and hot melt adhesive films

As consumers’ demand for clothing comfort and fashion continues to increase, seamless shirts, as an emerging product, are gradually occupying an important position in the market. The seamless bonding process of hot melt adhesive film is not only a technological advancement, but also provides an innovative solution for the clothing industry.

As a provider of seamless bonding technology and equipment, Alster has rich experience and high-quality product lines, focusing on providing efficient solutions for the garment manufacturing industry. In the production of seamless shirts, the use of related equipment and hot-melt adhesive films can greatly improve production efficiency and product quality.

The future of seamless shirts will pay more attention to the development trend of lightness, environmental protection and high-end, and the application of hot-melt adhesive film is undoubtedly an important driving force for this trend. If you have any questions or needs about the process and technology of seamless shirts, you can always consult professional manufacturers to learn more about hot melt adhesive film and seamless process to help improve the competitiveness of your products.