In the ever-evolving world of manufacturing, technology has paved the way for more efficient, cost-effective, and sustainable methods of production. One of the innovations that have significantly impacted various industries is the no sew adhesive bonding machine. This technology has revolutionized the way fabrics, textiles, and materials are bonded, replacing traditional sewing techniques with adhesive-based solutions. In this article, we will delve into the details of no sew adhesive bonding machines, explore their applications, benefits, and considerations, and provide insight into why they are becoming increasingly popular in various industries.

What Are No Sew Adhesive Bonding Machines?

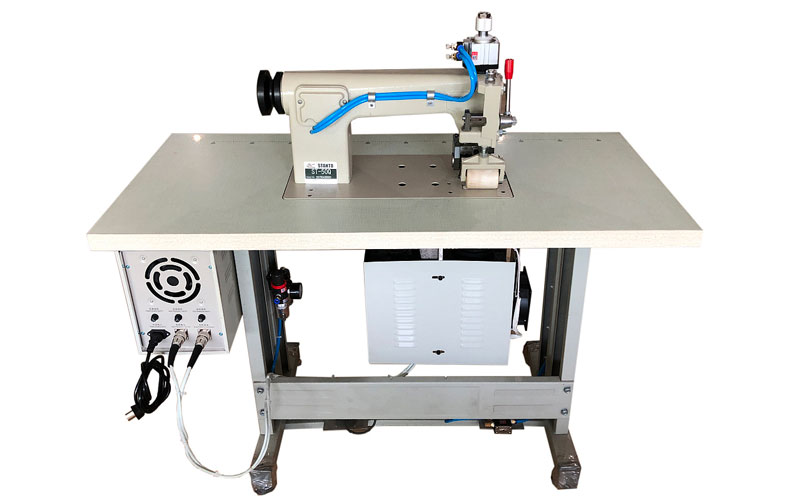

No sew adhesive bonding machines are advanced pieces of equipment designed to join materials together using adhesives instead of conventional sewing methods. These machines use a combination of heat, pressure, and adhesives to create a permanent bond between fabrics or materials without the need for thread or needles. The adhesive bonding process is faster and cleaner compared to traditional sewing, which makes it a preferred method for many manufacturers.

These machines can be used in a variety of industries, including textiles, automotive, medical, and fashion. Whether it’s bonding fabrics, nonwoven materials, leather, or other substrates, no sew adhesive bonding machines provide a versatile solution to create strong, durable bonds without the need for sewing.

How Do No Sew Adhesive Bonding Machines Work?

The working principle of no sew adhesive bonding machines revolves around the application of heat and pressure to melt an adhesive material, which then bonds the surfaces together. Here’s a step-by-step overview of how these machines typically work:

- Material Feeding: The materials to be bonded are placed into the machine. Depending on the machine design, this could involve rolling or feeding the materials through a conveyor system.

- Adhesive Application: A layer of adhesive, often in the form of film, liquid, or tape, is applied to one of the surfaces. The adhesive material can be pre-applied or applied during the bonding process, depending on the machine type.

- Heating: The adhesive is heated to its activation temperature. This is usually achieved using a heat press or radiant heat system, which causes the adhesive to melt and become tacky.

- Pressure Application: The materials are then pressed together under controlled pressure to ensure that the adhesive bonds to both surfaces evenly and firmly.

- Cooling and Setting: After the bond is formed, the adhesive cools down, solidifying the connection between the two materials.

- Output: The bonded materials are then ejected from the machine, ready for further processing or use.

This method of bonding offers a variety of advantages over traditional sewing techniques, such as increased speed, reduced labor costs, and a cleaner, more durable bond.

Benefits of No Sew Adhesive Bonding Machines

No sew adhesive bonding machines offer numerous benefits over traditional sewing methods. Some of the key advantages include:

1. Increased Speed and Efficiency

The no sew adhesive bonding process is significantly faster than traditional sewing. Since there is no need for thread insertion or stitching, the bonding process can be completed in a fraction of the time. This increased speed allows manufacturers to meet higher production demands and improve overall efficiency.

2. Cost-Effective

While there is an initial investment in no sew adhesive bonding machines, the long-term savings can be significant. There is no need for costly sewing threads, needles, or labor-intensive sewing processes. Additionally, the machines are often automated, reducing the need for manual labor and minimizing human error, further contributing to cost savings.

3. Cleaner and More Durable Bonds

Adhesive bonding creates smooth, uniform bonds that are often stronger and more flexible than traditional sewn seams. Unlike sewing, which can create bulky seams or stitches that are prone to wear and tear, adhesive bonds are seamless and provide a cleaner finish. This is especially important in industries where aesthetics and durability are critical, such as fashion and automotive upholstery.

4. Flexibility in Material Handling

No sew adhesive bonding machines are highly versatile and can handle a wide range of materials, including fabrics, nonwovens, plastics, and even some metals. This makes them ideal for industries that work with a variety of materials, such as automotive, medical, and textiles. Additionally, some machines are capable of bonding different thicknesses of materials, further expanding their range of applications.

5. Environmental Considerations

No sew adhesive bonding can be more environmentally friendly than traditional sewing, as it reduces the need for consumables such as thread and reduces material waste. Furthermore, some adhesive materials are designed to be biodegradable or recyclable, making them a more sustainable option compared to conventional methods.

6. Reduced Risk of Fabric Damage

Traditional sewing methods can sometimes result in fabric damage, such as stretching, tearing, or puckering. No sew adhesive bonding eliminates this risk, as there is no direct physical contact with the fabric (other than pressure during the bonding process). This results in a cleaner, more professional finish, especially for delicate materials.

Applications of No Sew Adhesive Bonding Machines

No sew adhesive bonding machines have found widespread use in a variety of industries. Here are some of the key sectors where these machines are commonly used:

1. Textiles and Fashion

In the fashion industry, no sew adhesive bonding machines are used to join fabrics without stitching. This technique is particularly useful for creating seamless garments, especially in high-end fashion and sportswear. It also allows for the creation of intricate designs, such as decorative appliques or embellishments, that would be difficult or time-consuming to achieve with traditional sewing methods.

2. Automotive Industry

The automotive industry makes extensive use of no sew adhesive bonding machines for upholstery and interior applications. These machines are used to bond fabrics, synthetic materials, and leather to create seats, door panels, headliners, and other interior elements. The strong, durable adhesive bonds ensure that the materials stay securely in place, even under extreme conditions.

3. Medical Applications

No sew adhesive bonding is also commonly used in the medical field for applications such as surgical drapes, medical gowns, and wound care products. The technology offers a hygienic and effective way to bond medical textiles without the need for stitches or staples, which can be uncomfortable or lead to infections.

4. Footwear and Leather Goods

In the footwear and leather industries, no sew adhesive bonding machines are used to create seamless shoes, boots, and other leather products. Adhesive bonding allows for a clean, durable bond that is ideal for materials that are difficult to sew, such as thick leather or rubber.

5. Aerospace and Defense

In the aerospace and defense sectors, no sew adhesive bonding machines are used for bonding high-performance materials in the construction of aircraft interiors, uniforms, and other specialized applications. These machines provide a lightweight, strong bond that is essential in industries where weight reduction and reliability are paramount.

Considerations When Choosing a No Sew Adhesive Bonding Machine

When selecting a no sew adhesive bonding machine, several factors should be considered to ensure that the equipment meets your needs. These include:

- Material Compatibility: Ensure that the machine can handle the types of materials you intend to bond. Some machines are designed for specific applications, while others are more versatile.

- Production Volume: Consider the speed and capacity of the machine. If you’re producing large volumes, you will need a high-speed, high-capacity machine that can keep up with your production demands.

- Adhesive Type: Choose the right adhesive material for your application. The type of adhesive (film, liquid, or tape) can vary depending on the desired bond strength, flexibility, and application.

- Automation and Ease of Use: Look for machines that offer automation and ease of use to reduce labor costs and improve consistency.

- Cost: While no sew adhesive bonding machines can provide cost savings in the long run, it’s important to consider the initial investment and whether it fits within your budget.

Conclusion

No sew adhesive bonding machines from Alster are a game-changing technology for industries looking to increase efficiency, reduce costs, and improve the quality of their products. By replacing traditional sewing methods with adhesive bonding, manufacturers can achieve faster production times, cleaner finishes, and more durable bonds. With applications spanning across textiles, automotive, medical, and aerospace industries, these machines have become indispensable in modern manufacturing processes. As technology continues to advance, the capabilities of no sew adhesive bonding machines are likely to expand, further solidifying their place as a valuable tool in a wide range of industries.