In recent years, the apparel industry has seen significant technological advancements that have not only improved manufacturing efficiency but also enhanced the quality and performance of garments. One such innovation that has had a transformative effect on garment production is the seamless bonding machine for seamless garment. This cutting-edge technology has revolutionized the production of seamless garments by eliminating the need for traditional stitching methods, offering a host of benefits ranging from improved comfort and durability to better aesthetics and increased production efficiency.

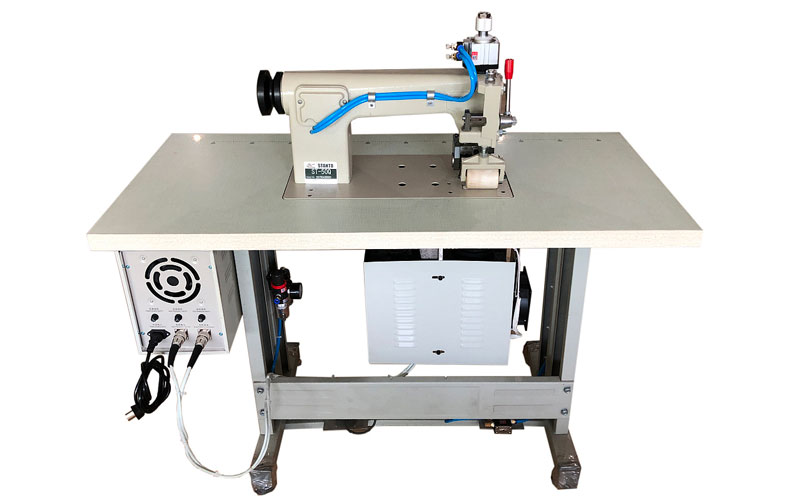

The seamless bonding machine is an essential tool in modern garment manufacturing. It allows fabrics to be bonded together without the use of thread or needles. Instead, it employs advanced bonding techniques such as heat sealing, ultrasonic welding, and adhesive bonding to fuse fabrics seamlessly. As a result, garments produced using seamless bonding machines are free from traditional seams, making them more comfortable, aesthetically appealing, and durable. This article will explore the functionality of seamless bonding machines, the benefits they bring to garment production, the types of seamless bonding technologies available, and the various applications in which they are used.

What is a Seamless Bonding Machine?

A seamless bonding machine is a highly specialized piece of equipment used in garment manufacturing to join two or more fabric layers together without the need for conventional stitching. This is achieved through a variety of bonding techniques, including heat sealing, ultrasonic bonding, and adhesive bonding. By using these methods, the seamless bonding machine creates a strong, durable bond between the fabric layers, resulting in garments that are both lightweight and comfortable.

One of the primary advantages of seamless bonding machines is that they eliminate the need for traditional seams. In conventional garment production, seams are created by stitching fabric pieces together with thread. These seams can be bulky, uncomfortable, and prone to fraying or unraveling. Seamless bonding machines, on the other hand, create a uniform bond that is smooth to the touch, without the added bulk of traditional seams. The absence of seams not only makes the garment more comfortable to wear but also improves its overall aesthetic appeal.

Key Benefits of Seamless Bonding Technology in Garment Production

Enhanced Comfort

One of the most significant benefits of using seamless bonding machines is the enhanced comfort of the resulting garments. Traditional seams can cause irritation and discomfort, particularly when they rub against the skin or are placed in areas that experience a lot of movement. This is particularly problematic in garments like activewear, sportswear, and shapewear, where comfort and freedom of movement are essential.

Seamless bonding eliminates this issue by creating smooth, flat bonds between fabric layers, without the need for bulky stitching. The result is a garment that fits more comfortably, feels softer on the skin, and minimizes the risk of chafing or irritation. This level of comfort is especially important for garments that are worn for extended periods or during physical activities.

Improved Durability

Seamless garments are also more durable than traditional garments with sewn seams. Traditional seams are often vulnerable to wear and tear, especially when subjected to regular movement or stretching. Seams can break, unravel, or weaken over time, leading to holes or frayed edges in the garment.

In contrast, garments made using seamless bonding technology are more robust and resistant to damage. The bonding process creates a strong, uniform connection between fabric layers, ensuring that the garment maintains its integrity even with repeated use. As a result, seamless garments tend to last longer, making them more cost-effective over time.

Aesthetic Appeal

The aesthetic benefits of seamless bonding are particularly apparent in the finished garment. Traditional seams can create a bulky appearance, especially when multiple layers of fabric are used. This can be particularly noticeable in tight-fitting garments like activewear, shapewear, and lingerie, where the presence of seams can affect the smoothness of the garment’s appearance.

Seamless bonding eliminates the need for visible seams, creating a smooth, streamlined look that enhances the overall design of the garment. Designers can also experiment with more intricate patterns and constructions, as the lack of seams allows for greater flexibility in design. This aesthetic advantage has made seamless garments highly sought after in the fashion industry, particularly in the production of high-end activewear, lingerie, and sportswear.

Increased Production Speed

Another major advantage of seamless bonding machines is the speed at which they can produce garments. Traditional garment manufacturing methods often involve a time-consuming process of cutting, stitching, and finishing. Seamless bonding machines, however, streamline this process by eliminating the need for stitching and reducing the amount of manual labor involved.

The bonding process is typically faster than traditional sewing methods, allowing manufacturers to produce garments more quickly. This not only increases production efficiency but also enables manufacturers to meet the growing demand for seamless garments in a timely manner.

Lower Manufacturing Costs

The use of seamless bonding technology can help reduce overall manufacturing costs in several ways. First, the elimination of stitching and the need for thread and needles can result in cost savings on materials. Second, the reduced need for manual labor, as the bonding process is largely automated, can lead to lower labor costs. Finally, the faster production time means that manufacturers can produce more garments in less time, improving overall productivity and profitability.

In addition to these direct cost savings, seamless bonding machines also minimize the likelihood of errors during production, which can lead to waste or the need for rework. This further helps to reduce costs and improve efficiency in the production process.

Types of Seamless Bonding Machine for Seamless Garment

There are several types of seamless bonding machines, each of which uses a different bonding technique to fuse fabric layers together. The most common types include:

Heat Sealing Machines

Heat sealing machines use high temperatures to melt a thermoplastic adhesive that bonds fabric layers together. The fabric is placed between two heated plates, and the adhesive melts, forming a strong bond when the plates cool. This technique is often used in the production of activewear, outerwear, and sportswear, as heat-sealed garments can also provide additional waterproofing and windproofing properties.

Ultrasonic Bonding Machines

Ultrasonic bonding machines use high-frequency sound waves to generate heat and bond fabric layers together. The ultrasonic waves cause the fabric fibers to vibrate, generating enough heat to melt the fibers and create a strong bond. This method is particularly effective for synthetic fabrics like nylon, polyester, and elastane. Ultrasonic bonding is precise and clean, making it ideal for high-end seamless garments such as lingerie, sports bras, and shapewear.

Adhesive Bonding Machines

Adhesive bonding machines apply a special adhesive to fabric surfaces and then press the fabric layers together under heat and pressure. This bonding technique is often used for delicate fabrics or intricate designs that may not be suitable for heat sealing or ultrasonic bonding. Adhesive bonding is common in the production of fashion garments, such as dresses, jackets, and accessories, where intricate details and a smooth finish are required.

Applications of Seamless Bonding Machines

Seamless bonding machines are used across a wide range of garment categories, including:

Activewear and Sportswear

Seamless garments are a perfect fit for activewear and sportswear due to their comfort, flexibility, and durability. Athletes and fitness enthusiasts require garments that allow for unrestricted movement, and seamless bonding machines ensure that activewear fits snugly and comfortably. Additionally, seamless garments are often lighter than their sewn counterparts, making them ideal for physical activities.

Lingerie and Shapewear

Seamless bonding technology has revolutionized the lingerie and shapewear industries by creating garments that fit better and feel more comfortable. Without traditional seams, these garments provide a smoother silhouette and eliminate the risk of visible lines under clothing. The comfort and aesthetic appeal of seamless lingerie and shapewear have made them extremely popular among consumers.

Swimwear

The benefits of seamless bonding are also evident in swimwear, where traditional seams can cause discomfort or irritation when exposed to water. Seamless swimwear offers a smooth, comfortable fit, and the lack of seams helps to reduce the risk of chafing during swimming or water sports.

Outerwear

Seamless bonding is also used in the production of outerwear, such as jackets, coats, and rainwear. The technology allows for the creation of garments that are lightweight, waterproof, and windproof, making them ideal for outdoor activities.

Conclusion

The seamless bonding machine has proven to be a revolutionary technology in the garment industry, offering numerous benefits that extend beyond just comfort. From improved durability and aesthetics to faster production times and reduced costs, seamless bonding machines are helping manufacturers create high-quality garments that meet the demands of modern consumers. As the demand for seamless garments continues to grow, the role of seamless bonding technology in the fashion industry will only become more significant, shaping the future of garment manufacturing and design. Looking for seamless bonding machine manufacturer? Contact Alster for details now!