With the continuous development of the fashion industry and the improvement of consumers’ demand for comfort and functionality, seamless underwear, as an emerging clothing product, is becoming more and more popular in the market. Seamless underwear has become one of the mainstream products in the modern underwear industry with its advantages of seamless design, comfortable fit, and free stretch. In the production process of seamless underwear, bonding technology, as a key process, plays a vital role. In order to meet the high-efficiency and high-precision production needs of seamless underwear, a variety of seamless bonding underwear machines have emerged on the market. This article will introduce the types, functions and applications of seamless bonding underwear machines in detail to help industry practitioners better understand and choose suitable equipment.

1. Basic Overview of Seamless Bonding Underwear Machine

The production process of seamless underwear mainly relies on thermal bonding, ultrasonic welding, hot pressing and other technologies, which replace traditional sewing and stitching processes to ensure the realization of seamless design. Seamless bonding underwear machine is a device specially designed for the production of seamless underwear. It can bond fabrics or other materials together by physical or chemical methods to ensure the comfort, firmness and beauty of underwear. According to different production needs and application fields, there are many types of seamless bonding underwear machines on the market, each with its own characteristics, which are widely used in the manufacture of underwear, sportswear, swimwear and other products.

2. Types of seamless bonding underwear machines

Seamless bonding machines (Seamless Bonding Machines)

Seamless bonding machines are equipment designed for seamless underwear, and are widely used in the production of underwear, sportswear, swimwear, etc. The equipment mainly achieves seamless splicing through the action of hot pressing and hot melt adhesive film. Seamless bonding machines are usually composed of heating systems, pressure systems and cooling systems. Through the combination of high temperature and pressure, the hot melt adhesive film is firmly combined with the fabric to achieve a seamless effect.

Features:

- Strong adaptability, able to handle various types of fabrics and materials.

- High efficiency, able to meet the needs of large-scale production.

- Adjustable temperature and pressure control to ensure bonding quality.

Application areas:

Suitable for the production of seamless products such as underwear, sportswear, swimwear, etc., especially underwear requiring high comfort and elasticity.

Heat Press Machines

Heat press machines are commonly used in the production of seamless underwear. They are suitable for bonding hot melt adhesive sheets or films to fabrics. By adjusting the temperature, pressure and time, the heat press machine can achieve the ideal bonding effect between fabrics and films, ensuring the seamlessness of underwear.

Features:

- High efficiency, capable of quickly completing mass production.

- Simple operation, suitable for large-scale industrial production.

- Adaptable to a variety of fabric types, can meet the production needs of different underwear products.

Application areas:

Mainly used for bonding the waist, shoulders, legs and other parts of seamless underwear, suitable for the production of high-comfort underwear, sports underwear, etc.

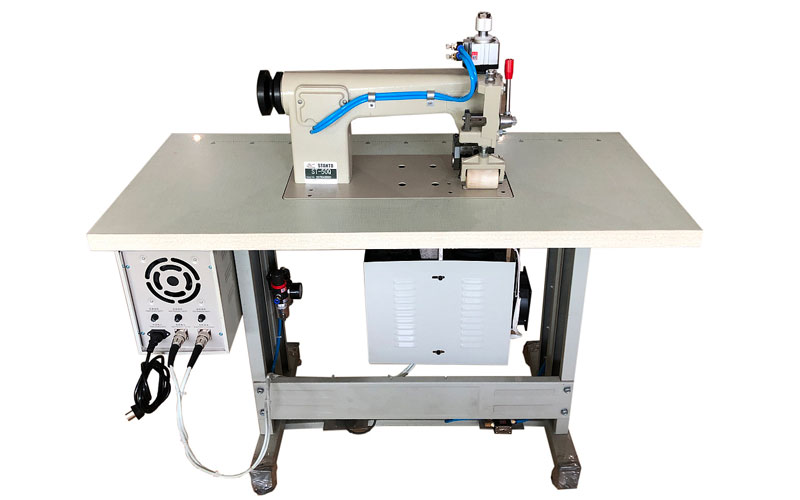

Hot Melt Adhesive Film Coating Machines

Hot Melt Adhesive Film Coating Machines are used to evenly coat hot melt adhesive film on the surface of fabrics to form a bondable layer. The coated fabric can be bonded by hot pressing, hot melting and other processes to ensure the comfort and firmness of seamless underwear.

![]()

Features:

- Precisely control the thickness of the film to ensure uniform coating.

- It can adapt to a variety of different fabrics and film materials.

- Provide flexible coating solutions to meet different production requirements.

Application areas:

Mainly used in the production of seamless underwear, providing basic materials for the coating of hot melt adhesive films, suitable for underwear, swimwear, sportswear and other products.

Ultrasonic Welding Machines

Ultrasonic welding machines use the vibration energy of high-frequency sound waves to locally heat the fabric to the melting point, and then weld the two layers of material together through pressure. This process does not require the use of glue or other adhesives, is environmentally friendly and efficient.

Features:

- No adhesive is required, and it is environmentally friendly.

- Fast welding speed, suitable for large-scale production.

- High welding strength, can ensure the firmness of seamless underwear.

Application areas:

Mainly used for local bonding and splicing of seamless underwear, such as splicing of waist, shoulders and other parts. Suitable for products with high bonding accuracy requirements.

Hot Melt Adhesive Cutting Machines

Hot Melt Adhesive Cutting Machines are used to cut hot melt adhesive films or films into suitable shapes and sizes so that they can adapt to different underwear designs. The equipment uses high temperature cutting technology to accurately control the shape and size of the adhesive film.

Features:

- High cutting accuracy, able to meet the requirements of complex underwear design.

- Improve production efficiency and reduce manual cutting errors.

- Flexible, can adjust the cutting size according to needs.

Application areas:

Mainly used for cutting hot melt adhesive films, suitable for multiple links in seamless underwear production, such as bonding of waist, shoulder and other areas.

Fully Automatic Seamless Garment Production Lines

Fully Automatic Seamless Garment Production Lines integrates a variety of seamless underwear production equipment to provide a fully automatic production line from material processing to finished product output. Through the intelligent control system, the production line can automatically complete all the production steps of underwear, greatly improving production efficiency.

Features:

- Fully automated, reducing manual operations and improving production efficiency.

- Highly integrated, reducing links in the production process and reducing production costs.

- The production mode can be flexibly adjusted according to different needs to adapt to the production of different styles.

Application areas:

Applicable to large-scale seamless underwear production, especially in first-class production enterprises that need to improve production efficiency and quality.

3. Selection basis of seamless bonding underwear machine

The selection of suitable seamless bonding underwear machine needs to be evaluated based on the following key factors:

- Production demand: Select suitable equipment according to production volume, product type and design complexity. Flexible stand-alone equipment can be selected for small batch production, while fully automatic production lines are recommended for large-scale production.

- Equipment stability: The stability and precision of the equipment are crucial to production quality. When selecting, it should be ensured that the equipment can operate stably for a long time to avoid affecting production efficiency due to equipment failure.

- Technical support: Select equipment suppliers that provide perfect technical support and after-sales service to ensure that problems in the equipment can be solved in time during the production process.

- Cost and return on investment: When selecting equipment, it is also necessary to consider the balance between the price of the equipment and production efficiency, and select equipment with a higher return on investment.

4. Conclusion

As one of the indispensable equipment in the production process of seamless underwear, the seamless bonding underwear machine has been continuously expanding in types and functions with the continuous advancement of technology. Understanding the functional characteristics and applicable scenarios of different types of seamless bonding machines is of great significance for improving production efficiency, ensuring product quality and meeting market demand. In the future underwear production, choosing the right seamless bonding equipment will help companies gain an invincible position in the fierce market competition. Want to get more about the seamless bonding machine? Welcome to contact Alster.