In the apparel manufacturing industry, fabric lamination has become a key technique for creating functional, durable, and visually appealing products. The use of thermoplastic hot melt adhesive films, particularly polyurethane (PU) hot melt films, has gained significant attention due to their versatile bonding properties and numerous advantages. This article explores the role of thermoplastic hot melt adhesive films, with a focus on polyurethane hot melt film glue, in apparel fabric lamination.

What is Thermoplastic Hot Melt Adhesive Film?

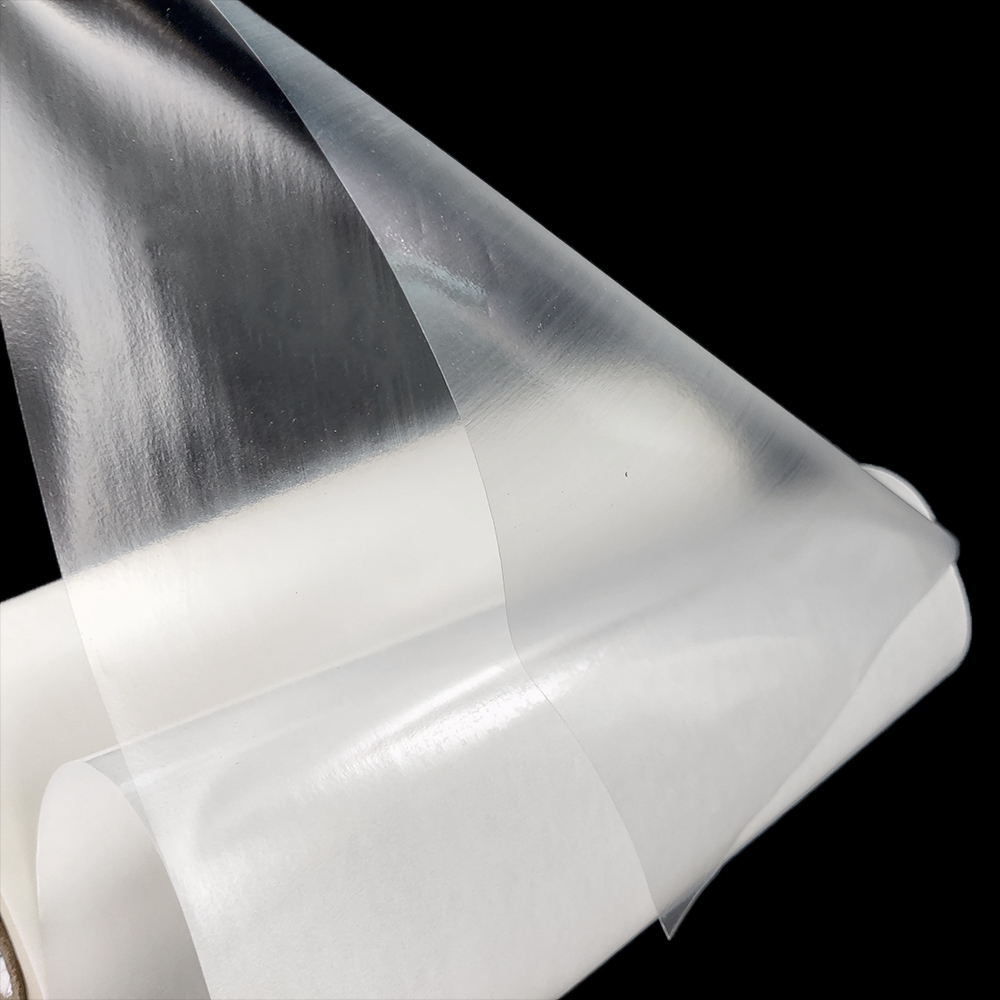

Thermoplastic hot melt adhesive films are a type of adhesive material that melts when heated and solidifies upon cooling. These films are typically used for bonding fabrics, textiles, and other materials, offering a fast, clean, and durable solution for manufacturing processes. Unlike traditional liquid adhesives, hot melt adhesive films come in a solid form, providing better control over application, reducing mess, and ensuring stronger bonds.

Polyurethane Hot Melt Film Glue for Apparel Fabric Lamination

Polyurethane hot melt films are made from a thermoplastic polymer that offers a variety of benefits, making them a popular choice for lamination in the apparel industry. These films have excellent adhesion properties, flexibility, and durability, making them ideal for bonding fabrics used in clothing, outerwear, and activewear.

Key Characteristics of Polyurethane Hot Melt Film Glue

Strong Adhesion

Polyurethane hot melt adhesive films offer strong bonding capabilities to a variety of materials, including polyester, cotton, nylon, and synthetic fabrics. This is especially important in the apparel industry, where durability and longevity are key factors in consumer satisfaction.Flexibility and Elasticity

One of the standout features of polyurethane hot melt films is their ability to maintain flexibility and elasticity after bonding. This makes them particularly suitable for activewear and sportswear, where stretch and movement are essential.Heat Resistance

Polyurethane films can withstand high temperatures without compromising their adhesive properties. This makes them an excellent choice for products that are subjected to heat during use, such as outdoor clothing or performance wear.Transparency

The transparency of polyurethane hot melt films ensures that the final product retains its aesthetic appeal without visible seams or glue marks. This is essential in creating clean, polished lamination for high-end apparel.Waterproof and Chemical Resistance

Polyurethane hot melt films offer excellent resistance to water, moisture, and chemicals, which is beneficial for creating waterproof clothing items or apparel that will be exposed to harsh environmental conditions.

Applications of Polyurethane Hot Melt Film Glue in Apparel Fabric Lamination

The versatility of polyurethane hot melt adhesive films makes them ideal for a wide range of applications in the apparel industry. Here are some of the most common uses:

1. Outerwear Lamination

Polyurethane hot melt films are often used in the production of laminated outerwear, such as jackets, coats, and raincoats. These films are bonded to the outer fabric, providing a waterproof and windproof layer that enhances the garment’s performance without adding unnecessary weight.

2. Sportswear and Activewear

The flexibility and elasticity of polyurethane films make them perfect for use in sportswear and activewear, such as running gear, yoga pants, and compression garments. These films provide superior bonding to stretch fabrics, ensuring that the garment maintains its shape and performance over time.

3. Protective Gear

Polyurethane hot melt adhesive films are also used in the lamination of protective gear, such as padding for sports or safety equipment. The durability and flexibility of these films ensure that the protective layers remain intact even during high-impact activities.

4. Fashion and High-End Apparel

Polyurethane films are used in the lamination of luxury fashion items, where aesthetics and performance are equally important. The ability to bond delicate fabrics without altering their appearance is a major advantage for designers looking to incorporate innovative lamination techniques.

Benefits of Using Thermoplastic Hot Melt Adhesive Films

Improved Durability and Strength

The strong and permanent bonds formed by polyurethane hot melt films significantly improve the durability of the laminated fabric. This is crucial for apparel that undergoes frequent use and washing.Enhanced Aesthetics

With its transparent finish, polyurethane hot melt film glue ensures that the appearance of the fabric is maintained, without the visible signs of glue that can occur with traditional adhesive methods.Sustainability

Polyurethane hot melt films are often more environmentally friendly than other adhesive options because they can be applied without the need for solvents. This reduces harmful emissions and supports more sustainable production processes.Faster Production Times

Hot melt adhesive films are easy to apply and require less drying time compared to liquid adhesives, resulting in faster manufacturing processes and improved production efficiency.Cost-Effective

The reduced waste and increased efficiency of using thermoplastic hot melt adhesive films make them a cost-effective solution for manufacturers looking to streamline production while maintaining high-quality standards.

Conclusion

Polyurethane hot melt adhesive films have revolutionized the apparel industry by offering a reliable, efficient, and cost-effective method for fabric lamination. With their strong adhesion, flexibility, transparency, and resistance to water and heat, these films are ideal for a wide range of applications in outerwear, sportswear, protective gear, and high-end fashion. As the demand for high-performance and durable fabrics continues to grow, the use of thermoplastic hot melt adhesive films will play an increasingly important role in shaping the future of apparel manufacturing.