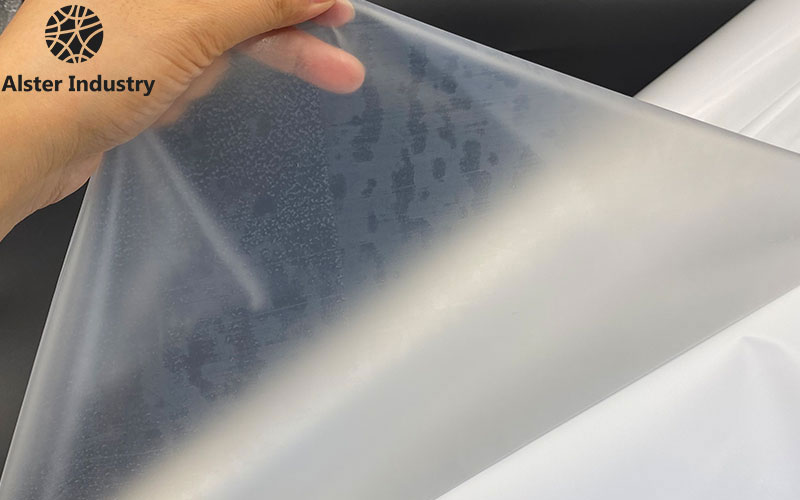

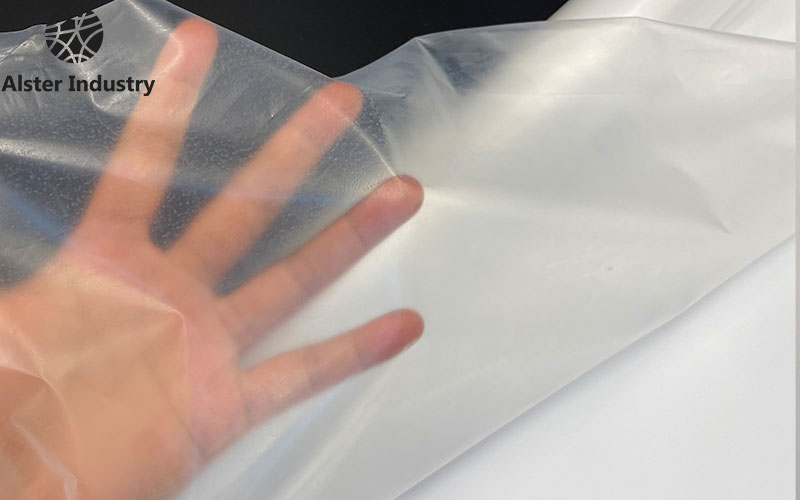

Want to know more about tpu hot melt adhesive films for laminating luggage? Let’s learn more about hot melt adhesive film first! Hot melt adhesive film is a widely used adhesive for modern composite materials. With its environmental protection, safety, and convenience, it has become an important raw material in many industries. Compared with traditional liquid adhesives, hot melt adhesive film is solid at room temperature and only becomes sticky when heated to a specific temperature, which makes it easier and safer to operate.

Since the production process does not contain harmful chemicals, hot melt adhesive film is not only environmentally friendly, but also avoids potential harm to human health. In addition, hot melt adhesive film has strong viscosity, good stability, and a wide range of applications. It can be seen in many fields from textiles, electronic products to luggage. In the production of luggage products, hot melt adhesive film has gradually replaced traditional adhesive materials with its excellent durability and environmental protection, and has become an important choice for luggage lamination.

What is TPU hot melt adhesive film?

Since we are talking about the types of TPU hot melt adhesive films for laminating luggage products today, let’s first understand what TPU hot melt adhesive film is. TPU hot melt adhesive film is a type of hot melt adhesive film. It has all the characteristics of hot melt adhesive film. Its main component is TPU. This material has the characteristics of multiple melting points, and its elasticity will increase with the increase of melting point temperature. That is to say, low-temperature TPU hot melt adhesive film has no elasticity, while high-temperature TPU hot melt adhesive film shows good elasticity.

Types of TPU Hot Melt Adhesive Film

In the production process of luggage products, TPU hot melt adhesive film has become an important composite material due to its excellent performance and diverse applications. TPU hot melt adhesive film is a type of hot melt adhesive film. It has the elasticity and durability of TPU material, and is environmentally friendly and non-toxic. It is widely used in the composite of luggage materials. The following are several main types of TPU hot melt adhesive films for luggage:

Low-temperature TPU hot melt adhesive film

Low-temperature TPU hot melt adhesive film can show good bonding performance at a lower melting point temperature, but its elasticity is relatively weak. It is suitable for the composite of materials with low bonding temperature requirements, such as some sensitive fabrics or luggage materials that require low-temperature operation. Low-temperature TPU hot melt adhesive film is usually used for bonding thinner luggage linings or accessories. Its advantages are simple operation and low energy consumption.

Medium-temperature TPU hot melt adhesive film

Medium-temperature TPU hot melt adhesive film is widely used in luggage products because it exhibits stable viscosity and moderate elasticity at a medium melting point, which can meet the bonding needs of most luggage materials. Medium-temperature TPU hot melt adhesive film is both durable and economical, and is suitable for luggage parts that are frequently used in daily life, such as the fabric composite of backpacks and the outer layer of handbags. The most commonly used for luggage is medium-high temperature TPU hot melt adhesive film, which has good elasticity and yellowing resistance

High-temperature TPU hot melt adhesive film

High-temperature TPU hot melt adhesive film can only play the best bonding performance at a high melting point. At the same time, it has extremely strong elasticity and durability, and is suitable for the composite of luggage materials with high strength and heat resistance requirements. This type of TPU hot melt adhesive film is often used in high-end luggage or luggage products that need to be used in harsh environments, such as travel suitcases, outdoor backpacks, etc., because it has excellent high temperature resistance, yellowing resistance and excellent tensile resistance.

Dual Melting Point TPU Hot Melt Adhesive Film

Dual Melting Point TPU Hot Melt Adhesive Film has the characteristics of multiple melting points and can show different properties at different heating temperatures. It provides adhesion at lower temperatures and exhibits strong elasticity and tensile properties at higher temperatures. This hot melt adhesive film is suitable for luggage materials that require complex composite processes, which can meet the use requirements of luggage in different environments while ensuring the bonding strength and durability of the materials.

Waterproof TPU Hot Melt Adhesive Film

Waterproof TPU hot melt adhesive film has good waterproofness and sealing properties, and is often used in outdoor or luggage products with high waterproof function requirements, such as waterproof backpacks, waterproof handbags, etc. This type of hot melt adhesive film can not only ensure the firm adhesion between materials, but also effectively resist the intrusion of external moisture or water.

Elasticity-enhanced TPU hot melt adhesive film

This type of TPU hot melt adhesive film is specially designed for luggage materials that require higher elasticity. It has excellent elasticity and tensile resistance and is suitable for use in sports backpacks or high-frequency luggage products. Elasticity-enhanced TPU hot melt adhesive film can ensure that the bonded material remains intact and strong after multiple pulls.

Characteristics of TPU hot melt adhesive film for luggage composite

TPU hot melt adhesive film for luggage composite has good low temperature and high temperature resistance. The lowest low temperature resistance can reach more than 20 degrees below zero, and the highest high temperature resistance can reach about 150°C. It also has certain elasticity and good water washing resistance. In addition, TPU hot melt adhesive film also has good adhesion and good bonding effect, long-lasting and durable without discoloration, and has certain waterproof performance, as well as the characteristics of easy transportation and storage. These characteristics can meet its application in the composite of luggage products.

The above is Alster’s introduction to the types of TPU hot melt adhesive films used for luggage and bag products. In general, all types of TPU hot melt adhesive films can be used for luggage and bag lamination. They have the characteristics of strong adhesion, good effect, cost saving, and environmental protection. More and more customers will tend to choose TPU hot melt adhesive films to laminate luggage and bag products. Different types are suitable for different luggage materials and usage scenarios. Customers can choose the most suitable TPU hot melt adhesive film type according to specific needs to ensure the quality and user experience of luggage products.