As one of the core equipment in clothing manufacturing, Flat Heat Press Machine is widely used in the pressing of seamless underwear, seamless clothing, sportswear and some delicate processes. With its efficient hot pressing technology, Flat Heat Press Machine can not only effectively complete the pressing process of waistband, trouser legs, hem and other parts, but also ensure the flatness, firmness and seamlessness of the product. This article will deeply analyze the functions, working principles, selection skills and price influencing factors of Flat Heat Press Machine to help you better choose and apply this equipment.

1. Functions and Applications of Flat Heat Press Machine

Seamless Underwear Pressing

In the process of making seamless underwear, the processing of waistband, trouser legs and hem is very important. Through the heating and pressurization of the flat heat press machine, the seams of the underwear can be pressed flat, ensuring that the product has a comfortable experience when worn, avoiding seam marks, and improving appearance and quality.

Hem and hem pressing

For hem processing of trouser legs, hems and other parts, the flat heat press can heat evenly and efficiently complete the pressing, so that the trouser legs and hems are wrinkle-free and have clear lines, which meets the design requirements.

Pressing of other straight parts of clothing

In addition to seamless underwear, flat heat presses are also widely used for hot pressing of straight parts of other clothing. For example, sportswear, casual wear, underwear outerwear, etc., through precise hot pressing to ensure the shape of the clothes is stable and the appearance is flat.

2. Characteristics of flat heat press machines

The flat heat press machine has many unique designs and functions to meet different process and production requirements. Here are some of the main features:

Thickened and reinforced body design

The thickened body structure helps to improve the stability of the heat press, especially under long-term operation and high-load working conditions, which can effectively reduce vibration and unnecessary displacement. The brake wheels and fixed foot cups make the equipment more stable during movement and work, avoiding offset during production.

Time/Temperature/Piece Count CNC Display

Flat-type heat presses are usually equipped with precise CNC display systems, with intuitive operation interfaces that clearly display parameters such as time, temperature, and piece count. Users can set them precisely according to different fabrics and process requirements to ensure the accuracy of each press. Such systems not only improve operating efficiency, but also ensure the quality consistency of each batch of products.

Double-guide slider system

Traditional heat presses often have the problem of head offset, especially in large models, which may cause uneven heat pressing. The upward sliding double-guide slider system of the flat-type heat press can effectively solve this problem, making the heat press more accurate when working and ensuring that there is no offset during the pressing process.

Automatic sensing and manual operation modes

Flat-type heat presses support two modes: automatic sensing and manual operation. In automatic sensing mode, the device can automatically start pressing according to the placement of the fabric, while in manual mode, the operator can control the pressing through buttons. The flexibility of this function enables the heat press to adapt to different production needs, whether it is large-scale production or small-scale customization.

Adjustable heating plate lifting speed

Flat-type heat presses are usually equipped with an adjustment function, allowing the operator to adjust the speed of the heating plate lifting according to the characteristics of different materials. At the same time, the cylinder pressure can also be adjusted, usually set between 0-8KG/cm, to ensure the precise processing of different fabrics during the heat pressing process.

Uniform heating

High-quality flat-type heat presses are usually equipped with multiple heating modules, and the common configuration is three heating modules. The heating module can ensure the uniformity of heating and avoid local overheating or underheating. The low-end version may only be equipped with the upper heating module, which is suitable for some simple heating needs.

3. Working process of flat-type heat press

The working process of flat-type heat press usually includes the following steps:

Temperature and time setting

First, set the required temperature and time according to production needs. Different materials have different requirements for temperature and time. For example, the pressing of seamless underwear requires a lower temperature, while some heavy fabrics may require a higher temperature.

Fabric laying

Place the fabric to be hot-pressed on the heating plate to ensure that the fabric is laid flat to avoid wrinkles and bubbles affecting the hot-pressing effect.

Automatic or manual pressing

During operation, the machine will automatically sense or manually press the pressing rod to apply pressure according to the set mode. The pressing process will make the fabric fully contact with the hot plate to complete the hot-pressing and bonding work.

Heating and pressing

The heating plate maintains a constant temperature within the set time. While heating, pressure acts on the fabric to ensure that it achieves the effect of hot-pressing and bonding. The heating module will evenly transfer heat to each part of the fabric to avoid uneven quality caused by temperature difference. The whole process can be precisely controlled according to different fabrics and process requirements.

Time setting and automatic control

Within the set time, the hot press will maintain stable pressure and temperature to ensure that the pressing effect of each product meets the standard. The automatic timing function of the equipment will automatically stop after the set time ends to avoid excessive heating and pressing. For semi-automatic mode, the operator needs to manually control the time and operation, but this mode is usually suitable for small batches or special requirements.

Product removal and post-processing

After the hot pressing process is completed, the product will be removed from the heating plate, and usually a slight cooling process is required to ensure that its shape remains stable. In some cases, post-processing, such as trimming the edges or additional bonding, can also be performed to ensure the quality of the final product.

Here is an operation video about how to use the flat heat press machine, for more about this machine, you can contact Alster, our sales manager will send you details!

4. How to choose the right flat heat press machine?

Choosing the right flat heat press machine is crucial to improving production efficiency and product quality. The following are key factors to consider when choosing:

Size and customization requirements

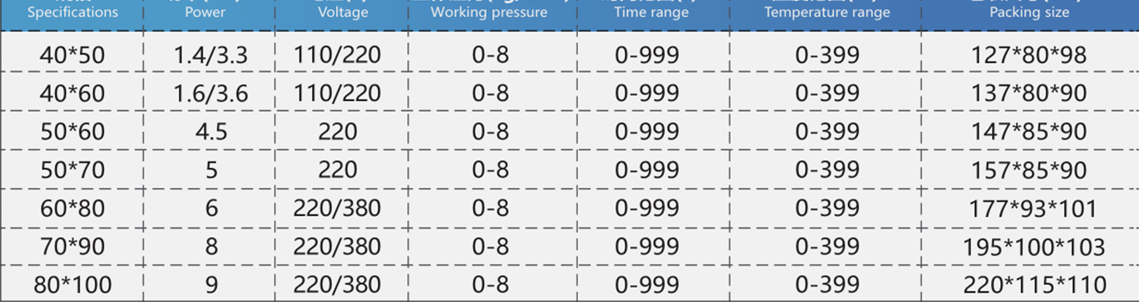

Different production needs have different requirements for the size of the flat heat press machine. Flat heat presses are usually available in a variety of standard sizes, including 40×50, 40×60, 50×60, 50×70, 70×80, 80×100, etc. Choosing the right size according to the production scale and product characteristics can improve production efficiency and reduce waste.

If the production line involves multiple types of products or special specifications of fabrics, customized sizes and panels are also an option. Customization can help manufacturers meet production needs more accurately and improve work efficiency.

Type of heating module

The heating module of the flat heat press machine has an important impact on the performance and service life of the equipment. The heating modules on the market are divided into domestic and imported. Common imported module brands include high-end equipment from Germany, Japan and other countries. Imported modules usually perform well in heating uniformity, stability and durability, but their prices are relatively high.

Although domestic modules are relatively cheap, they may be slightly inferior in stability and uniformity under long-term operation at high temperatures. If the budget allows, choosing imported modules will achieve better performance and stability in long-term use.

Automation and operation mode

Depending on the production needs, equipment with different degrees of automation can be selected. For mass production or efficient production lines, it is a more efficient choice to choose a flat heat press in semi-automatic or fully automatic mode, which can greatly improve production speed and consistency.

For small-batch production or high-end customized production, manual mode or manual-automatic combined mode is more flexible, and the operator can control the pressure and time according to the specific situation to adapt to different production needs.

Body stability and structural design

The thickened and reinforced body design is an important factor in improving the stability of the flat heat press, especially when working at high frequencies. If the equipment is not stable enough, it may cause uneven heat pressing and affect the quality of the final product. Choosing equipment with strong body support can effectively avoid problems such as machine vibration and displacement, and ensure consistent quality of each pressing.

Heat press equipped with brake wheels and fixed foot cups can further enhance the stability of the equipment, especially during movement and operation. Ensuring that the equipment remains stable during operation helps improve work efficiency.

Cylinder pressure and lifting speed adjustment

Different processes have different requirements for pressure and lifting speed, so it is very important to adjust the cylinder pressure and heating plate lifting speed. Generally, the adjustable range of cylinder pressure of flat heat press is 0-8KG/cm, and the appropriate pressure can be selected according to the thickness of the fabric and the pressing requirements.

The adjustment function of the lifting speed can be flexibly set according to production needs, so as to ensure that the material is subjected to appropriate pressure and time during the hot pressing process to avoid damage or uneven treatment.

5. Price influencing factors

The price of flat heat press machine is affected by multiple factors. Understanding these factors can help you make a wise choice within your budget.

Source of heating module

Imported heating modules (such as those from Germany and Japan) are usually more expensive, with more stable performance, and are suitable for high-standard and high-efficiency production needs. Domestic modules are relatively affordable and suitable for some cost-sensitive applications. Choose the right module source according to production budget and needs.

Machine size and customization

The size and customization requirements of the equipment directly affect the price. Standard-sized flatbed heat presses are usually cheaper, while customized-sized or specially configured equipment will increase the cost. Choose the right size according to production needs to avoid waste or failure to meet production needs due to the selection of too large or too small equipment.

Functional configuration and degree of automation

The functional configuration of the flatbed heat press, including the degree of automation, the number of heating plates, the complexity of the control system, etc., will affect the price. For example, equipment with a higher degree of automation is usually more expensive, while semi-automatic or manually operated equipment is cheaper. According to the production scale and process requirements, choosing the right automation configuration can ensure efficiency while controlling costs.

Production capacity and equipment performance

The production capacity (such as the number of pieces produced per hour) and performance of the flatbed heat press will also affect the price of the equipment. Equipment with high production capacity is usually more expensive, but it can effectively improve the efficiency of large-scale production. If your production needs are low, you can choose a more basic model to reduce costs.

Conclusion

Flat-type heat press machine is an indispensable and important equipment in modern clothing manufacturing, especially in seamless underwear, seamless clothing and high-precision pressing processes. When choosing a suitable flat-type heat press, it is necessary to consider a variety of factors such as production scale, process requirements, budget, etc. This article introduces the functions, working process, selection skills and price influencing factors of flat-type heat press in detail, hoping to help you make a wise purchasing decision. When choosing equipment, you should pay attention to the performance and stability of the equipment, and also reasonably choose the appropriate configuration according to the actual production needs to ensure production efficiency and product quality.