Have you ever wondered how some of the cleanest, strongest seams in synthetic materials are made—without a single thread in sight? Welcome to the world of ultrasonic sewing machines, where innovation meets precision.

If you’re involved in manufacturing, textile design, or product development and looking for cleaner, faster, and more efficient alternatives to traditional sewing, this is the guide you’ve been waiting for. In this post, we’ll take a deep dive into the ultrasonic sewing machine—what it is, how it works, why it’s a game-changer, and how to choose the right one for your business.

Let’s get stitching—without the stitches!

What Is an Ultrasonic Sewing Machine?

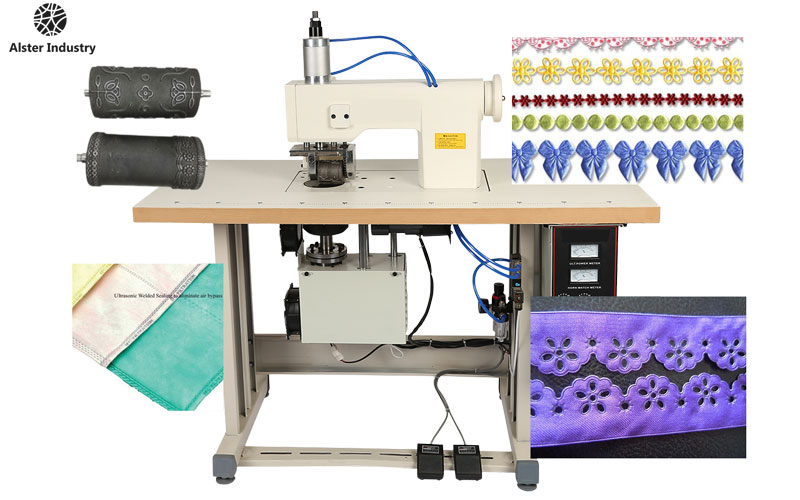

At its core, an ultrasonic sewing machine is a device that uses high-frequency ultrasonic vibrations to bond materials together. Instead of needles, threads, or glue, it relies on heat generated by sound waves to fuse thermoplastic materials.

This process is often referred to as ultrasonic welding or seamless bonding, and it’s commonly used on synthetic fabrics such as polyester, nylon, and polypropylene—materials that melt under heat and pressure. Think of it as “welding for fabric.”

How Does an Ultrasonic Sewing Machine Work?

Let’s break down the magic behind ultrasonic sewing.

The Technology Behind the Scenes

Ultrasonic Generator

Converts standard electricity into high-frequency energy (typically 20–40 kHz).Transducer

Transforms that energy into mechanical vibrations.Booster & Sonotrode (Horn)

Amplifies and delivers vibrations to the material.Anvil Roller

Presses against the horn, creating the pressure needed to fuse the material.

The result? When the horn contacts the material over the anvil roller, localized heat melts and bonds the fibers together. The moment it cools, the material is permanently fused.

No threads. No punctures. No residue.

What Makes Ultrasonic Sewing So Special?

If you’re used to traditional sewing machines, the leap to ultrasonic may feel like jumping into the future. But once you see the benefits, you’ll understand why more and more industries are making the switch.

✅ 1. No Thread, No Needle, No Fuss

Forget replacing broken needles, winding bobbins, or rethreading machines every 30 minutes.

✅ 2. Super Speed

Ultrasonic sewing is incredibly fast—seams can be bonded in a fraction of the time required by traditional sewing.

✅ 3. Cleaner, Safer Products

Since no glue or thread is involved, there’s no risk of contamination. That’s especially critical for medical and hygiene products.

✅ 4. Strong and Seamless

The bonds created are often stronger than sewn seams, and they’re airtight and watertight too.

✅ 5. Eco-Friendly

No adhesives, solvents, or extra materials means lower environmental impact and waste.

✅ 6. Versatile Applications

From fashion to automotive to food packaging—ultrasonic machines do it all.

Who Uses Ultrasonic Sewing Machines?

Ultrasonic sewing is not just for big factories. Businesses of all sizes across various industries are embracing this technology.

👗 Apparel & Fashion Industry

Lingerie, swimwear, sportswear

Nonwoven accessories

Decorative designs

🏥 Medical & Hygiene Industry

Face masks and surgical gowns

Disposable scrubs and head covers

Diapers and sanitary products

🚗 Automotive Sector

Interior linings and panels

Car seat covers

Sound insulation layers

🛍️ Packaging & Industrial Use

Thermoplastic bag sealing

Blister pack welding

Shopping bags and wrappers

🏠 Home Textiles

Upholstery seams

Bed linens

Shower curtains and blinds

What Materials Are Compatible?

Ultrasonic sewing machines work best with thermoplastic materials. These fabrics become soft and moldable when heated, which is key to ultrasonic bonding.

Most Suitable Materials:

Polyester (PET)

Polypropylene (PP)

Nylon

Thermoplastic Polyurethane (TPU)

Acetate

Nonwoven fabrics (spunbond, meltblown, etc.)

🛑 Not suitable: Natural fibers like 100% cotton or wool unless blended with synthetics.

Types of Ultrasonic Sewing Machines

Ultrasonic machines come in a few different flavors depending on your production scale and application needs.

1. Handheld Ultrasonic Welders

Ideal for small-scale repairs or sampling

Portable and easy to use

Limited to basic seam jobs

2. Table-Top Machines

Good for small businesses or custom manufacturing

Perfect for masks, garments, or prototyping

3. Semi-Automatic Machines

Better for medium-scale production

Operator feeds material, machine bonds automatically

4. Fully Automatic Ultrasonic Lines

High-volume industrial use

Programmable with integrated feeding and cutting

Used in medical, hygiene, and automotive sectors

How to Choose the Right Ultrasonic Sewing Machine

Buying an ultrasonic sewing machine isn’t just about the price tag. Here are a few tips to help you find your perfect match:

1. Know Your Materials

Make sure your fabric is compatible. Some suppliers even offer bonding tests.

2. Check Frequency and Power

20 kHz = deeper welds, good for thicker materials

35–40 kHz = fine detailing, better for delicate fabrics

3. Speed & Output Needs

Look at how many units/hour you need to produce. Manual vs. automated makes a huge difference.

4. Customization

Do you need decorative seams, embossing, or ultrasonic cutting too? Some machines can be tailored.

5. Support & Training

Choose a supplier who offers training, manuals, and reliable tech support.

6. Maintenance & Spare Parts

Ask about the availability of replacement parts and estimated maintenance schedules.

Maintenance Tips for Long-Term Performance

Like any high-tech machine, ultrasonic welders need regular TLC. Here’s how to keep your machine humming:

Clean the horn and anvil roller regularly to avoid build-up.

Check alignment between horn and anvil to ensure perfect bonding.

Listen for unusual sounds—they could signal a misaligned transducer.

Avoid fabric with debris or oils that could damage the horn.

Follow manufacturer’s schedule for calibration and inspection.

A well-maintained ultrasonic sewing machine can last for years with minimal downtime.

Common Problems & Troubleshooting

| Problem | Possible Cause | Fix |

|---|---|---|

| Weak bonding | Low power or pressure | Adjust settings, check horn alignment |

| Material burning | Power too high | Reduce amplitude, shorten welding time |

| Fabric slipping | Roller worn or loose | Replace roller, adjust tension |

| Loud buzzing | Horn damage or misalignment | Stop machine, inspect horn and booster |

| Uneven seams | Dirty horn or anvil | Clean contact surfaces |

Don’t forget: Routine training and good habits = fewer problems.

Trends to Watch in Ultrasonic Sewing

As automation and eco-consciousness sweep across industries, ultrasonic technology is leveling up.

🔹 Smart Features

Some machines now include digital displays, sensors, and feedback systems to control amplitude and welding time.

🔹 IoT Integration

Real-time monitoring and analytics for production performance and maintenance forecasting.

🔹 Compact Designs

Smaller, modular units for startups and mobile production.

🔹 Greener Manufacturing

Ultrasonic = no solvents, no adhesives, less waste—perfect for green brands.

Real-Life Use Case: Mask Manufacturing Boom

During the COVID-19 pandemic, the demand for ultrasonic sewing machines surged. Why?

Because surgical masks require:

Seamless edge bonding

Sterile, threadless finishing

High-speed production

Ultrasonic machines allowed small and large manufacturers alike to scale quickly and meet public health needs. Some factories scaled from 1,000 masks/day to over 100,000/day using ultrasonic automation.

Where to Buy Ultrasonic Sewing Machines

Looking to add ultrasonic tech to your facility? Here are some tips:

Start with trusted industrial suppliers that offer after-sales support.

Ask for a trial or sample bonding.

Compare specs, not just prices.

Make sure training is included.

Buy a machine with room to grow, especially if you plan to scale.

Final Thoughts: Is Ultrasonic Sewing Right for You?

Ultrasonic sewing machines aren’t just a trend—they’re a revolution in how we bond and fabricate synthetic materials.

Whether you’re:

A startup making eco-friendly sportswear,

A medical supplier producing sterile disposables,

Or a packaging company wanting cleaner sealing—

Ultrasonic sewing is a powerful, efficient, and future-ready solution.

No more threads. No more glues. Just clean, fast, and flawless bonding.

Welcome to contact Alster – we’re manufacturing different types of seamless bonding machine and ultrasonic sewing machine.