Lace is a delicate and decorative fabric widely used in fashion, home décor, and crafts. Traditionally, lace is sewn onto fabrics using stitching methods, but with advancements in technology, ultrasonic lace machines have revolutionized the process. These machines use ultrasonic vibrations to bond lace to various fabrics efficiently, eliminating the need for traditional sewing techniques. This article will explore how ultrasonic lace machines work, the step-by-step process of attaching lace to fabrics, the benefits of using ultrasonic bonding, and tips for achieving the best results.

1. Understanding Ultrasonic Lace Machines

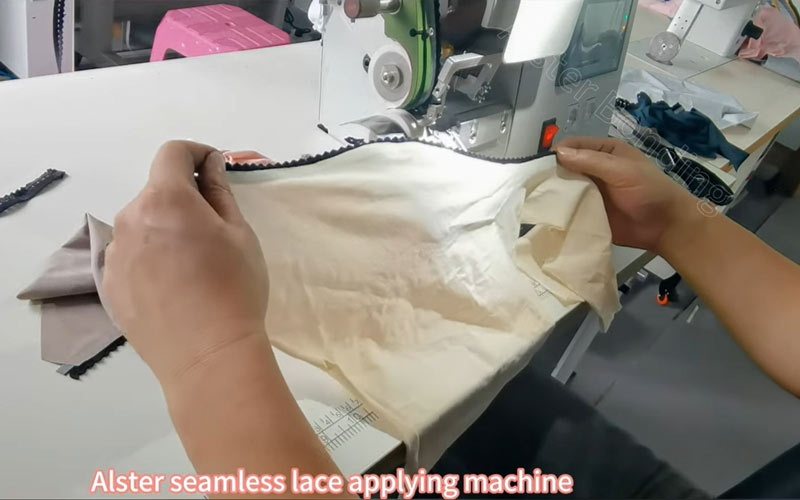

An ultrasonic lace machine is a specialized device that uses high-frequency ultrasonic waves to generate heat through vibration. This heat creates a seamless bond between lace and fabric without requiring threads or adhesives. The machine works by pressing the lace and fabric together with a roller while ultrasonic energy fuses them at the molecular level.

Key Components of an Ultrasonic Lace Machine

- Ultrasonic Generator: Produces the high-frequency electrical signals that drive the machine.

- Transducer: Converts electrical signals into mechanical vibrations.

- Horn (Sonotrode): Directs ultrasonic energy to the lace and fabric.

- Pressure Roller: Applies pressure to ensure even bonding.

Ultrasonic lace machines are widely used in garment manufacturing, lingerie production, and textile applications where decorative lace edges and seamless fabric bonding are required.

2. Step-by-Step Guide to Attaching Lace to Fabrics

Step 1: Prepare the Lace and Fabric

Before using an ultrasonic lace machine, ensure that both the lace and the base fabric are clean and free of dust or lint. Depending on the application, lace can be attached to fabrics like cotton, silk, polyester, or non-woven materials. Tips for fabric selection:- For synthetic fabrics (such as polyester and nylon), ultrasonic bonding works best because these materials have thermoplastic properties.

- For natural fabrics (such as cotton and linen), a synthetic lace or an interfacing layer may be needed for optimal adhesion.

Step 2: Adjust the Ultrasonic Lace Machine Settings

Set up the machine by adjusting the following parameters:- Ultrasonic frequency (typically between 20kHz and 35kHz).

- Power level to ensure strong bonding without burning the fabric.

- Pressure settings on the roller to control the depth of fusion.

- Speed of the roller to match the thickness and delicacy of the lace.

Step 3: Position the Lace on the Fabric

Place the lace on the fabric in the desired position. It is important to keep the lace aligned evenly to achieve a neat and professional finish. Use fabric clips or a guiding mechanism to hold the lace in place. Common lace placement techniques:- Overlay method: The lace is placed over the fabric, and the edges are fused together.

- Edge attachment: The lace is attached along the fabric’s edge, creating a decorative border.

- Inset method: The lace is cut and bonded within the fabric to create intricate patterns.

Step 4: Start the Ultrasonic Bonding Process

- Turn on the ultrasonic lace machine.

- Guide the lace and fabric through the machine smoothly and evenly.

- The ultrasonic waves will generate heat and pressure, bonding the lace to the fabric instantly.

- Move the fabric at a consistent speed to avoid irregular bonds or burns.

Step 5: Inspect and Trim Excess Lace

After bonding, check the attachment for consistency and strength. Trim any excess lace or uneven edges to refine the final appearance. If needed, repeat the bonding process for extra reinforcement.3. Benefits of Using Ultrasonic Lace Machines

1. No Need for Thread or Adhesives

Unlike traditional sewing, ultrasonic bonding does not require threads, needles, or glues, making it a cost-effective and time-saving process.

2. Strong and Durable Bonding

The ultrasonic fusion creates a strong and seamless attachment between lace and fabric, making it more durable than stitched lace, which may unravel over time.

3. Faster Production Process

Ultrasonic lace machines work at high speed, significantly reducing the time needed to attach lace compared to hand-sewing or glue application.

4. Aesthetic and Clean Finish

The process produces clean, sealed edges with no visible stitching, enhancing the overall appearance of lace decorations.

5. Suitable for Delicate and Thin Fabrics

Unlike sewing machines that can damage delicate lace, ultrasonic bonding applies minimal pressure, preserving the integrity of fragile fabrics.

6. Environmentally Friendly

Since ultrasonic bonding does not require chemical adhesives, it is a more eco-friendly method that reduces fabric waste and harmful emissions.

4. Tips for Achieving the Best Results

- Use high-quality lace: Cheap lace may not bond well and could fray easily.

- Test on a sample first: Before working on the final fabric, always test the machine on a scrap piece to ensure the settings are correct.

- Ensure even pressure: Uneven pressure can result in weak bonds or burned areas.

- Maintain the machine: Regular cleaning and maintenance of the ultrasonic horn and roller will improve performance and longevity.

- Work in a dust-free environment: Dust and lint can interfere with the bonding process, so keep the workspace clean.

5. Applications of Ultrasonic Lace Machines

Ultrasonic lace machines are widely used in:

- Fashion and apparel: Seamless lace bonding in lingerie, bridal dresses, and blouses.

- Home textiles: Attaching lace to curtains, tablecloths, and pillow covers.

- Medical textiles: Sealing lace on non-woven surgical gowns and face masks.

- Automotive textiles: Decorative lace applications in car interiors.

Conclusion

The ultrasonic lace machine is a game-changer in the textile industry, offering a seamless, efficient, and cost-effective way to attach lace to fabrics. By using ultrasonic vibrations, this technology eliminates the need for traditional stitching or adhesives, resulting in strong, durable, and aesthetically pleasing fabric-lace bonds. Whether you are in fashion production, home décor, or industrial applications, an ultrasonic lace machine can enhance your manufacturing efficiency and product quality.

Would you like more details on specific machine models or troubleshooting tips? Or Are you looking for machines? Welcome to contact Alster!