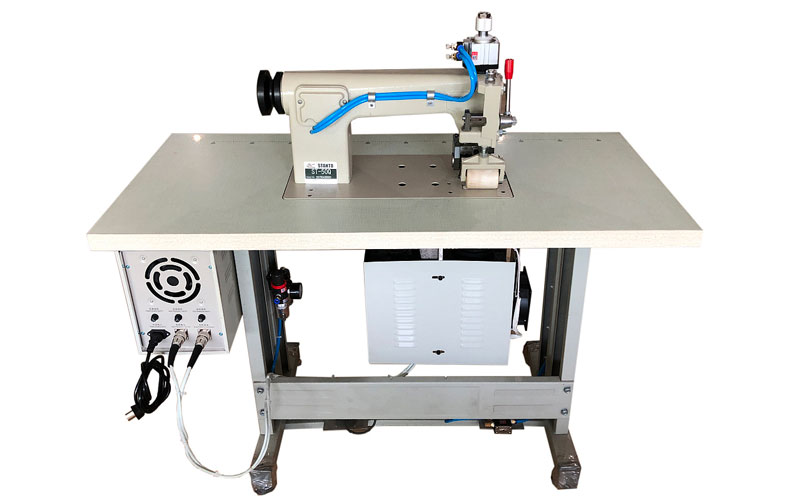

As an advanced equipment widely used in the modern textile industry, the multifunctional bonding machine has become an essential tool for many clothing manufacturers with its excellent performance and multiple functions. With the continuous improvement of the clothing industry’s requirements for production efficiency, precision, and product quality, traditional manual operation and single-function equipment can no longer meet the needs of the market. The multifunctional bonding machine has been widely used in many fields due to its easy operation, diverse functions, and high efficiency. This article will introduce in detail the characteristics of the multifunctional bonding machine and the tasks it can complete.

Features of the Multifunctional Bonding Machine

Simple Operation

The multifunctional bonding machine adopts touch screen control, with an intuitive interface and simple operation. The operator only needs to make simple settings according to production requirements to easily adjust parameters such as temperature, pressure, and speed, thereby realizing various production processes. Both novice and experienced operators can quickly get started and improve production efficiency.

Convenient Mold Change

The machine supports the rapid replacement of molds to meet different types of production needs. During the production process, mold replacement is very convenient, without the need for complex tools, reducing the time for mold change and improving production flexibility and efficiency.

Multifunctional

The multifunctional bonding machine integrates multiple bonding methods, such as taping, overlapping, folding, and U-type wrapping. These functions can be completed by one machine to meet the production needs of different styles and fabrics, greatly improving the diversity and adaptability of production.

Excellent Performance

The machine is equipped with four heating devices, located at the top and bottom of the machine, to ensure uniform heat transfer during the bonding process and increase the bonding strength. The heating system can heat up quickly to achieve the ideal bonding effect, ensuring high quality and high efficiency of production. In addition, the machine is also equipped with free pressure adjustment and independent speed control systems, which can be adjusted according to the characteristics of different fabrics, adapt to various types of fabrics, and ensure the best bonding effect.

High Automation

The multifunctional bonding machine is equipped with an automatic temperature control system, which can automatically adjust the temperature according to the needs of different fabrics and hot melt adhesive films to avoid the impact of human operation errors. At the same time, the automatic feeding system can intelligently control the tension of the adhesive film to ensure that each piece of adhesive film is used evenly without loosening or over-tightening, greatly improving the stability and consistency of production.

What Can a Multifunctional Bonding Machine Do?

The wide range of functions of the multifunctional bonding machine has made it widely used in clothing manufacturing, especially in the production of some non-standard clothing, sportswear, underwear, and other high-quality products. The following are some common applications of multifunctional bonding machines:

Overlapping

Overlapping bonding is a common function of the multifunctional bonding machine, which is suitable for overlapping bonding of fabrics or fabrics. By adjusting the temperature and pressure of the machine, the overlapping parts can be firmly bonded together to ensure the firmness and beauty of the seams. This function is very suitable for processing positions such as trouser legs and skirts, avoiding the unevenness caused by traditional sewing methods and the disadvantages of textiles not being easy to stretch.

Folding

The multifunctional bonding machine can also perform fine folding processing, which is suitable for the production of underwear, T-shirts, yoga pants, and other clothing. Through the folding process, the fabric can be folded accurately according to the design requirements, avoiding the errors and irregularities that occur during manual folding. The high-precision control of the machine ensures that each fold is consistent, greatly improving production efficiency and quality.

U-type Wrapping

U-type wrapping is another common application function, suitable for waist, neckline, and other parts that need wrapping. Through the U-shaped wrapping process, a precise wrapping effect can be achieved to ensure the overall beauty and comfort of the garment. This technology is particularly suitable for the production of sports bras, sports pants, and high-end clothing, and can provide stronger elasticity and comfort.

Taping

The taping process is one of the core functions of the multifunctional bonding machine, which is suitable for bonding treatment of waist, trouser legs, and other parts. In this process, the hot melt adhesive film is precisely bonded to the surface of the fabric, making the seams of the garment not only stronger but also avoiding the unevenness and wear problems in the traditional sewing process.

Conclusion

The multifunctional seamless bonding machine has been widely used in modern clothing manufacturing with its excellent performance, flexible functions, and efficient automation. It can not only meet the production needs of different fabrics and clothing styles but also improve production efficiency, reduce production costs, and improve product quality and appearance. The high-quality multifunctional bonding machine provided by Alster has become a must-have equipment for clothing manufacturers to improve their competitiveness and optimize production processes with its outstanding technical advantages. If you need to know more about the multifunctional bonding machine, please feel free to contact us, Alster will provide you with the most professional equipment and services.